The ability to produce high-quality metals at the lowest possible unit cost is the most fundamental factor in the success of industries that produce or consume metals. This is why Optical Emission Spectrometers (OES), devices that help analyse the elemental composition of metals, have become essential in the industrial landscape. For sectors where safety, performance, and compliance are non-negotiable – like automotive, aerospace, and defence – ensuring stringent metal quality is vital, but so too is the need to be cost-efficient. This article explores how advanced OES technology is increasingly crucial in driving quality improvements, cost optimisation and even Industry 4.0 adoption across critical industries.

Maintaining metal quality is not merely an onerous checklist item but a vital responsibility for ensuring safety, performance, and regulatory compliance across industries, particularly in critical and strategic ones like automotive, aerospace, defence, construction, railways, power, etc. The quanta and combinations of elements present in the metal impart or impair various mechanical and quality parameters, including, among others, ductility, conductance, strength, wear resistance, corrosion resistance, machinability, etc.

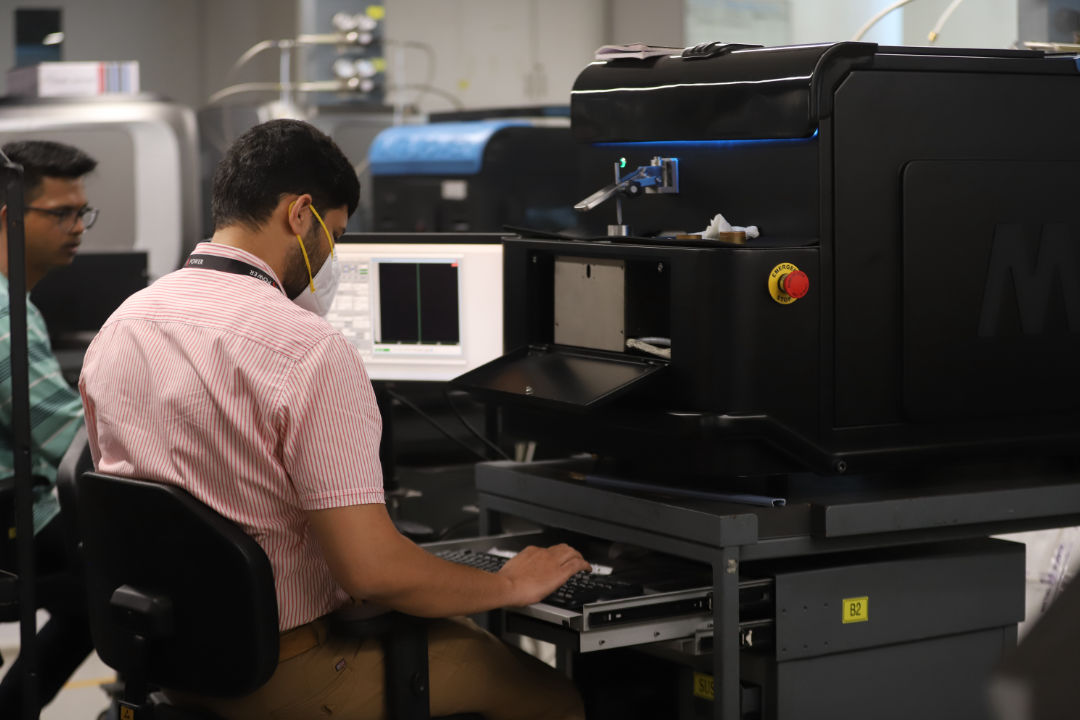

It is obvious, therefore, that for high-quality applications, extremely accurate and granular analysis of elemental composition is an absolute must. For decades, Spark Optical Emission Spectrometers (OES for short) have been and remain the go-to solution for elemental analysis in metal production and testing. They offer an unmatched level of accuracy and precision in elemental composition analysis while also offering the widest elemental coverage and the most rapid results among all potential analytical solutions. These devices are used by virtually all players in the metals supply chain, right from manufacturers who use analyses for melt optimization and control to the end-use industries who use them to ensure the quality of what they purchase.

It’s also about the money, honey!

While OES are not particularly “cheap” or “low-cost” (though, of course, these are all relative terms), just like all investments in quality improvement, they provide phenomenal returns on investment. Most users recover their investments in under six months through raw material cost savings! A high-quality OES allows users to play at the margins of elemental concentration requirements, saving money on higher-cost raw materials.

Also, measuring accurately while the molten metal is still in the furnace ensures that the extremely energy- (and therefore cost-) intensive melt process never has to be redone based on failure to meet elemental concentration requirements. There are, of course, other benefits to using an OES, such as the ability of material scientists and metallurgists to develop new and alternative materials or grades. Overall, an OES offers tremendous upsides to productivity, profitability, and research.

Evolution of OES Technology

Spark OES isn’t a new field. It’s been around for nearly a century but has evolved increasingly rapidly. Early OES models, which have been used since the 1950s, used photomultiplier tubes (PMTs) as detectors. These were extremely large – often room-sized, were limited in elemental coverage thanks to being able to measure only one wavelength per PMT, and were also very expensive and maintenance-heavy. As optical and electronic systems evolved, these instruments became more compact and rapid, but the inherent limitations of PMTs formed explicit constraints on size, cost, and scalability.

Over the initial decades, most advances in the field were limited to optical elements – most specifically, gratings, where improvements in groove density and reflectivity led to performance improvements and form factor reductions. The advent and, more importantly, the transformational upshift in the resolution of Charge-Coupled Devices (CCD) and, more recently, Complementary Metal Oxide Semiconductors (CMOS) detectors led to the most recent and most transformational rounds of revolution in the field of OES. Linear array CMOS detectors, now a staple in the most advanced OES systems, carry 2000 pixels (or more) per detector, and with their exceptional sensitivity, readout speeds, compactness and stability, offer OES manufacturers the ability to build systems that are far more compact, economical, and flexible than the PMT systems of yore, and yet, match or beat said PMT-based systems on every performance and price measure going.

CMOS-based OES also eschew large single optics systems in favour of compact and optimized dual-optics systems, use Argon-filled optics instead of vacuum for the deep UV regions, and cover the full continuous spectral range instead of discreet wavelengths, therefore offering more compact, economical, stable, and flexible solutions, which are also more future-proof – since the continuous spectral coverage ensures that elements of interest can be added at-site without hardware upgrades at any point in the product lifecycle – something that was impossible to do on PMT systems.

Multiple other advancements have also been made ‘under the hood.’ Data rates, redundancies, ease of operation, and servicing spectrometers have seen quantum leaps in the last decade. From Oxygen to Mercury and Potassium to Hydrogen, there is virtually no stable naturally-occurring element in the world that today’s modern OES can’t analyse accurately, and down to low and even sub-ppm levels. Evidence, if any, were needed that the age of technology is no bar to its innovation potential and proof that when it comes to technological advancements, old dogs not only can, but indeed do, learn the newest tricks.

The Impact of Integration and Industry 4.0

Modern OES systems have embraced Industry 4.0, incorporating advanced integration capabilities. Real-time data transmission to remote devices, seamless communication with laboratory management systems, and enhanced diagnostics have made spectrometers smarter and more user-friendly. These instruments now include built-in automatic diagnostics and real-time maintenance alerts, ensuring proactive system monitoring and reduced downtime.

Integration with cloud-based systems allows for remote monitoring, app-based alerts, reports generation, and data analysis, as well as integration with other data-monitoring and process-optimization or automation systems aligning OES with the demands of even the most modern of manufacturing facilities. In their latest avatar, OES systems are moving towards automation and operator-less analysis Laboratories where samples are prepared and analyzed, and results are fed into relevant control systems without human intervention.

Future of Metal Testing in High-Performance Industries

The progression of OES technology has significantly elevated the quality of metal testing and analysis, driving improvements in myriad industries. From ensuring the quality of safety-critical components to enhancing manufacturing cost-efficiency, OES plays a critical role. As businesses and industries advance, future developments will continue pushing the boundaries of accuracy, precision, speed, functionality, automation, and ease of use.