As India’s semiconductor industry gears up for exponential growth, manufacturers face a critical challenge: ensuring their equipment can withstand the corrosive materials essential to modern production. From aggressive process gases to potent wafer cleaning agents, these substances test the limits of traditional materials, leading to increased downtime and maintenance costs. But what if you could eliminate these challenges with one simple solution? NBK’s chemical-resistant screws and components are here to revolutionize your manufacturing process.

What Are Process Gases?

Process gases are a group of inert and specialized gases essential in various stages of semiconductor manufacturing, including film formation and etching processes. However, many of these gases exhibit corrosive properties that can even degrade robust materials like stainless steel (e.g., SUS304). Examples include Hydrogen Bromide and Chlorine Trifluoride. Therefore, the equipment used in these processes require corrosion-resistant components.

What Are Wafer Cleaning Agents?

Wafer cleaning agents are specialized chemical solutions designed to remove dirt, contaminants, and minute impurities from semiconductor wafers. These agents ensure that the wafer surface is pristine before the next processing stage. However, their powerful cleaning action can also dissolve metals, including stainless steel, presenting a challenge for equipment longevity. Manufacturers must carefully select materials for their equipment to resist the corrosive effects of these cleaning agents

Innovative Solutions: Chemical-Resistant Screws

To address the challenges posed by corrosive gases and liquids, NBK offers a range of chemical-resistant screws. These screws exhibit exceptional corrosion resistance, making them suitable for environments where exposure to process gases or wafer cleaning agents is unavoidable.

Metal Screws:

- Tantalum: Hex Socket Head Cap Screws (SNSTA)

- Hastelloy C-22 & C-276: Socket Head Cap Screws (SNSH-C22, SNSH-C276)

- Inconel: Socket Head Cap Screws (SNSI)

- SUS316L & SUS310S: Socket Head Cap Screws (SNSL, SNSJ)

- Titanium: High Intensity Titanium Alloy Screws (SNSTG)

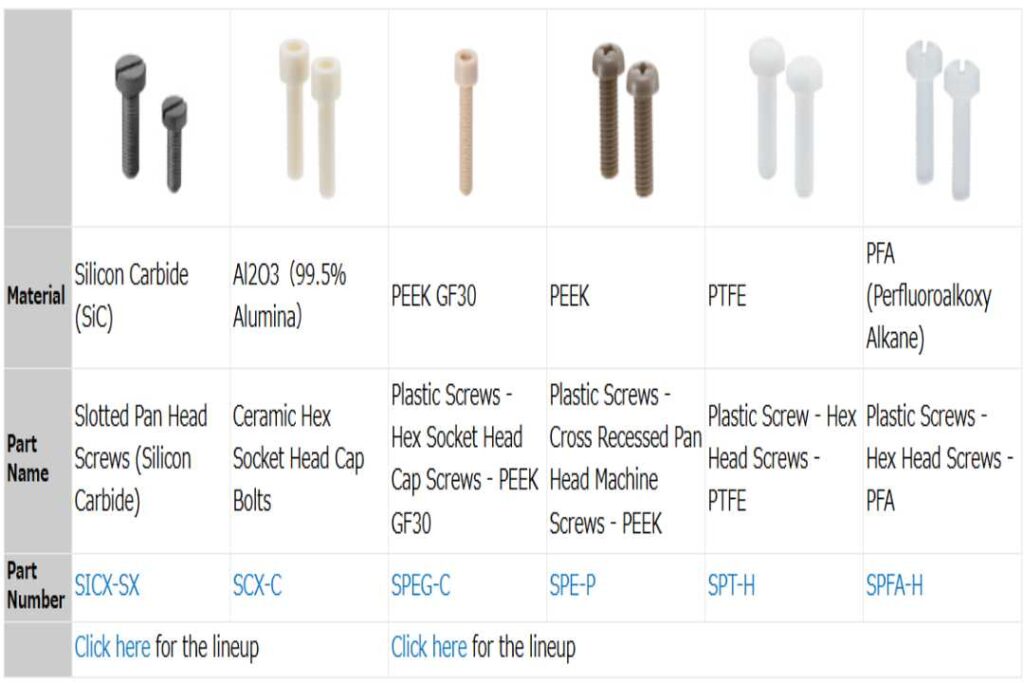

Ceramic and Resin Screws

- Silicon Carbide (SiC): Slotted Pan Head Screws (SICX-SX)

- Alumina (99.5%): Ceramic Hex Socket Head Cap Bolts (SCX-C)

- PEEK and PTFE: Plastic Screws for various applications

These materials are carefully selected to withstand the extreme environments found in semiconductor manufacturing, offering a reliable solution for extended operational efficiency.

Silicon Carbide (SiC): Proven Performance

Silicon Carbide (SiC) is a ceramic material with excellent heat and chemical resistance, second only to diamond in hardness (New Mohs Scale: Diamond = 15, Silicon Carbide = 13). NBK’s SiC screws offer outstanding resistance to harsh, corrosive environments.

Free Catalog: Your Guide to Advanced Solutions

NBK not only offers screws but also provides other mechanical components, such as couplings, tailored for semiconductor manufacturing. These solutions, along with detailed case studies, are compiled in the catalog below.