In semiconductor manufacturing, equipment is subjected to extreme temperature fluctuations, reaching up to 1000°C in certain zones. This constant change in temperature poses a significant challenge to the integrity and performance of machine components, especially fasteners. Components must withstand repeated heating and cooling without warping, loosening, or seizing to ensure long-term durability, performance, and safety. NBK (Nabeya Bi-tech Kaisha) has engineered an extensive lineup of screws and fasteners specifically designed to excel in high-temperature and thermal cycling environments, making them ideal for semiconductor applications.

Understanding Thermal Cycling

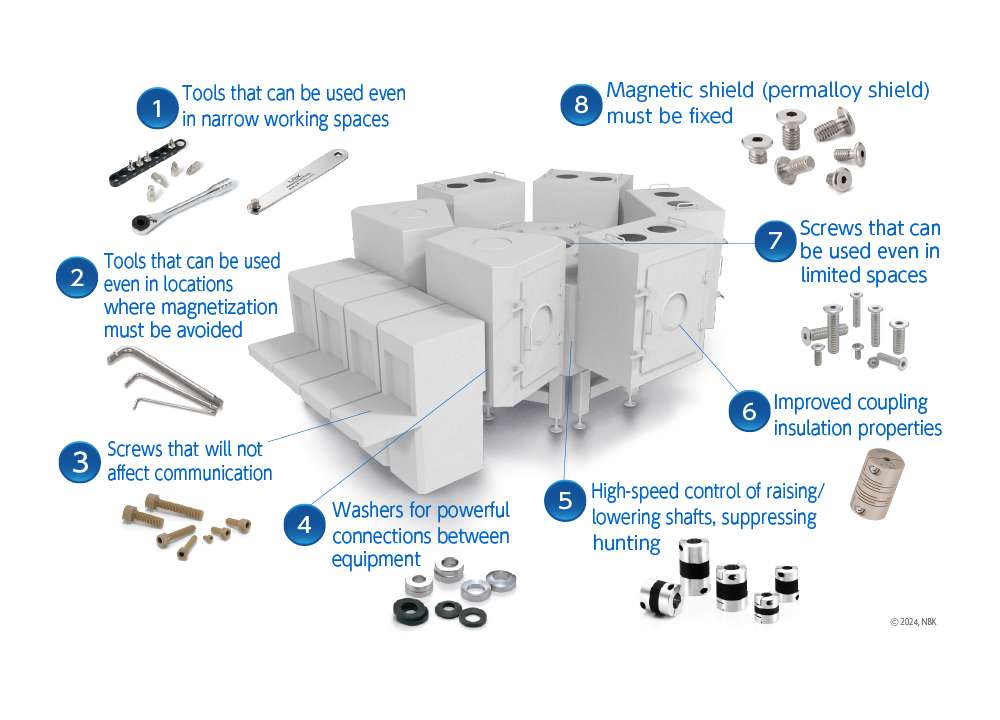

Thermal cycling refers to the repeated and rapid fluctuations in temperature that occur in semiconductor manufacturing processes. Key equipment such as ion implantation systems, photolithography tools, etching machines, and coating systems can experience internal temperatures from 200°C up to 1000°C. These shifts cause materials to expand and contract repeatedly, leading to fatigue, deformation, or mechanical failure in standard components.

High-heat-resistant Screws

NBK addresses these challenges with specially engineered screws capable of withstanding extreme temperatures:

- Tungsten (SNCW) and Pure Molybdenum (SNSM) screws offer incredibly high melting points—3683°C for tungsten and 2623°C for molybdenum—making them ideal for the hot zone like ion generators in ion implantation equipment, light sources in lithography equipment, etc.

- Tantalum (SNSTA) and Inconel (SNSI) options provide excellent corrosion resistance and mechanical stability under high thermal loads.

- Silicon Carbide (SICX-SX) and Alumina Ceramic (SCX-C) screws extend the lineup for situations demanding chemical inertness and insulation properties.

These materials resist deformation under extreme heat and maintain mechanical integrity throughout repeated cycles of thermal stress.

Performance in Vacuum Conditions

In semiconductor manufacturing, many processes occur in vacuum environments, requiring materials that do not outgas or lose their properties. NBK offers: Inconel (SVSI) and Molybdenum (SVSM) screws with ventilation holes to support degassing and maintain vacuum purity.

These screws are machined with precision and can be cleaned and packaged in the clean room to minimize particle generation, supporting optimal process conditions in lithography and etching chambers.

Seizing Prevention

Due to thermal expansion and material adhesion, repeated temperature fluctuations can cause galling or seizure in threaded components. NBK counters this with a variety of surface treatments and coatings:

- MoS₂ Coating (SNSS-MO) provides dry lubrication for reduced friction.

- PTFE (SNSS-TF) and Fluorine (SNSS-FC) coatings enhance corrosion resistance while preventing seizure.

- Surface hardening treatments like on SUS316L (SNSL-PN) enhance wear resistance and make the screws ideal for repeated thermal cycling environments.

Other functional options, such as low-temp black chrome, are also available.

Loosening Prevention

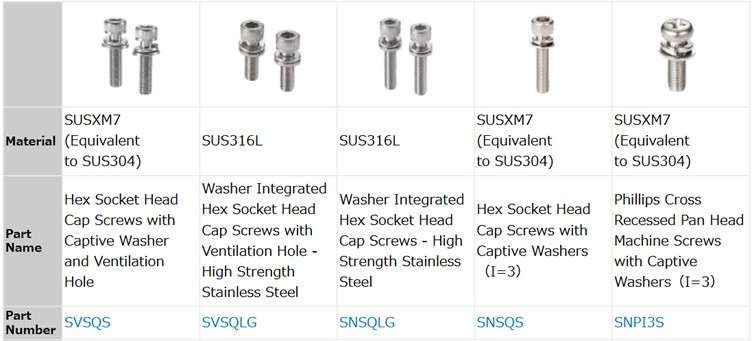

Thermal expansion can loosen traditional fasteners, leading to component instability and alignment issues. NBK provides integrated washer screws that absorb this thermal movement and maintain fastening force:

- Captive washer screws such as SVSQS, SVSQLG, and SNSQLG include integrated spring washers that compensate for expansion and contraction.

- Titanium options (SNSI3T) and specialized configurations like SEMS screws offer lightweight and vibration-resistant alternatives, ideal for compact assemblies and sheet metal applications.

Conclusion

NBK’s comprehensive portfolio of screws engineered for high-temperature and thermal cycling environments reflects a deep understanding of the demanding conditions in semiconductor manufacturing. By combining advanced materials, precision engineering, and thoughtful design features—like surface treatments, ventilation holes, and integrated washers—NBK ensures fastening components’ longevity, reliability, and performance in extreme applications.

As the semiconductor industry advances, the reliability of every small component becomes increasingly critical. NBK’s innovative solutions make it a trusted partner in achieving mechanical stability and performance in the most challenging thermal environments.

Download NBK’s catalogue to explore more semiconductor industry solutions.