Hengst is showcasing its advanced liquid and air filtration technologies at the IAA Transportation in Hanover (September 17-22, 2024), including a groundbreaking CO2-neutral filter. As a leader in filtration and fluid management, Hengst is evolving its offerings to meet future demands. To continue delivering cutting-edge solutions, the company has consolidated its basic research and development efforts at the TechCenter Filtration in Münster. This facility focuses on addressing future challenges and developing solutions that support the transition to sustainable mobility and energy. At the IAA Transportation, Hengst will highlight how its innovations contribute to reducing environmental and air pollution.

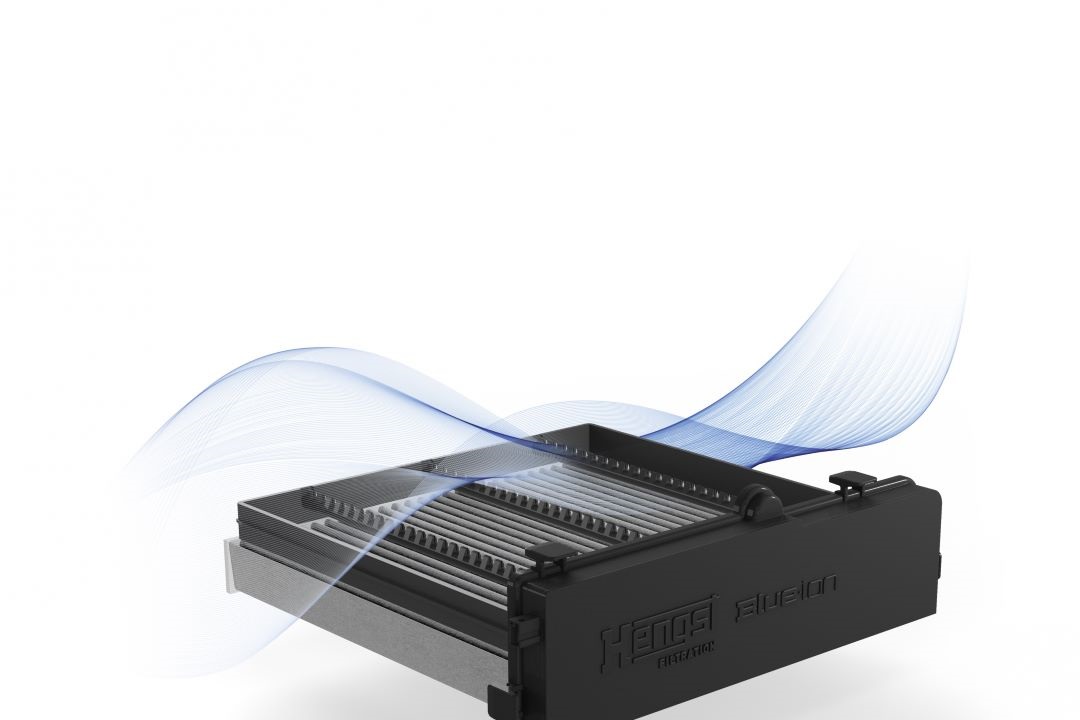

Electrified Cabin Air Filter Blue.ion

Hengst leverages its extensive expertise in industrial filtration to develop advanced solutions for vehicle air filtration, exemplified by the Blue.ion cabin air filter. This filter utilizes both ionization and polarization to enhance its effectiveness. Positioned in front of the filter, the ionizer charges airborne particles electrostatically, facilitating their separation within the filter. While ionization alone might diminish the filter’s charge over time, polarization maintains the charge by creating an electrostatic field, ensuring consistent performance.

Solutions for Alternative Fuels (e-Fuels, FAME, HVO)

The shift towards decarbonizing the transport sector, including off-highway and stationary applications, necessitates a diverse range of drive and fuel technologies. This variety addresses the unique requirements across different segments and global regions. Applications may involve electric drives with batteries or fuel cells, as well as combustion engines using synthetic fuels like e-fuels and hydrogen, or biofuels such as hydrogenated vegetable oils (HVO) and fatty acid methyl esters (FAME).

Hengst is advancing its fuel filter technology to support these alternative fuels. The Blue.maxx fuel filter system is designed to handle all types of fuels, whether fossil, biogenic, or synthetic. To accommodate the varied needs of modern engines in commercial and off-highway vehicles, Hengst has created a modular system that can be easily customized for original equipment or retrofitting. The system offers flexibility with single or multi-layer elements of the Energetic fuel filter insert to meet specific separation, fineness, and fuel requirements.

The Blue.maxx system can be configured as either a two-part setup with a pre-filter and main filter or a combined main filter with integrated water separation. It includes four basic models for flow rates ranging from 50 to 750 liters per hour, with options for customization using various additional components.

Filter Systems for Hydrogen Engines and Fuel Cells

When developing hydrogen-powered combustion engines, it’s crucial to address challenges such as potential water accumulation in engine oil and the flammability of hydrogen. Hengst addresses these issues with specially designed synthetic filter elements and sealing materials. Their oil filter modules are adaptable to meet the needs of hydrogen engines and other alternative fuels like FAME and HVO. To mitigate the risk of explosive mixtures from blow-by gases in hydrogen engines, Hengst has developed an advanced active ventilation system. This system features specialized air valves that introduce fresh air into the crankcase, maintaining a positive pressure gradient and reducing ignition risks. The active ventilation is integrated into a comprehensive filter solution, which includes the electrically driven Blue.tron disk separator, ensuring optimal engine oil separation based on engine speed and load.

In fuel cells, aging can introduce ions into the coolant, necessitating effective filtration for safe operation. Hengst’s Blue.iox ion exchanger delivers exceptional protection with minimal maintenance. Its innovative filter cartridge design, featuring axial flow and a mixed bed resin system for both cation and anion exchange, ensures high filtration efficiency throughout the service interval, rapidly reducing ion concentration in the coolant.

Fuel cells also demand precise air filtration to maintain long service life and performance. Hengst’s multi-layer cathode air filter system effectively removes particles and substances such as nitrogen oxides, ammonia, and sulfur oxides. This modular system accommodates a broad range of fuel cell power outputs from 100 to 500 kilowatts. Additionally, Hengst provides solutions for direct system integration on the fuel cell stack, including a water separator for anode gas recirculation with an innovative valve configuration for purge and drain.