In a significant move towards promoting sustainable mobility and a circular economy, Tata Motors, one of India’s leading automobile manufacturers, has inaugurated two cutting-edge Registered Vehicle Scrapping Facilities (RVSFs) under the Re.Wi.Re – Recycle with Respect initiative. Located in Lucknow (Uttar Pradesh) and Raipur (Chhattisgarh), these facilities are equipped to safely dismantle end-of-life vehicles and handle both passenger and commercial vehicles across all brands, including two- and three-wheelers.

The inauguration was conducted virtually by Nitin Gadkari, Union Minister for Road Transport and Highways, Government of India. The Minister highlighted the importance of these new centers in supporting the National Vehicle Scrappage Policy, which encourages citizens to transition to more environmentally friendly and fuel-efficient vehicles through structured incentives. He commended Tata Motors for establishing these modern facilities, which not only ensure the responsible disposal of vehicles but also enable the recovery of valuable materials through scientific recycling.

“These centers represent a significant step forward in vehicle dismantling, ensuring the safe recycling of components while contributing to sustainability efforts across India,” Shri Gadkari said. “Such initiatives are key to creating an efficient and impactful vehicle scrappage ecosystem that will benefit the environment and the economy.”

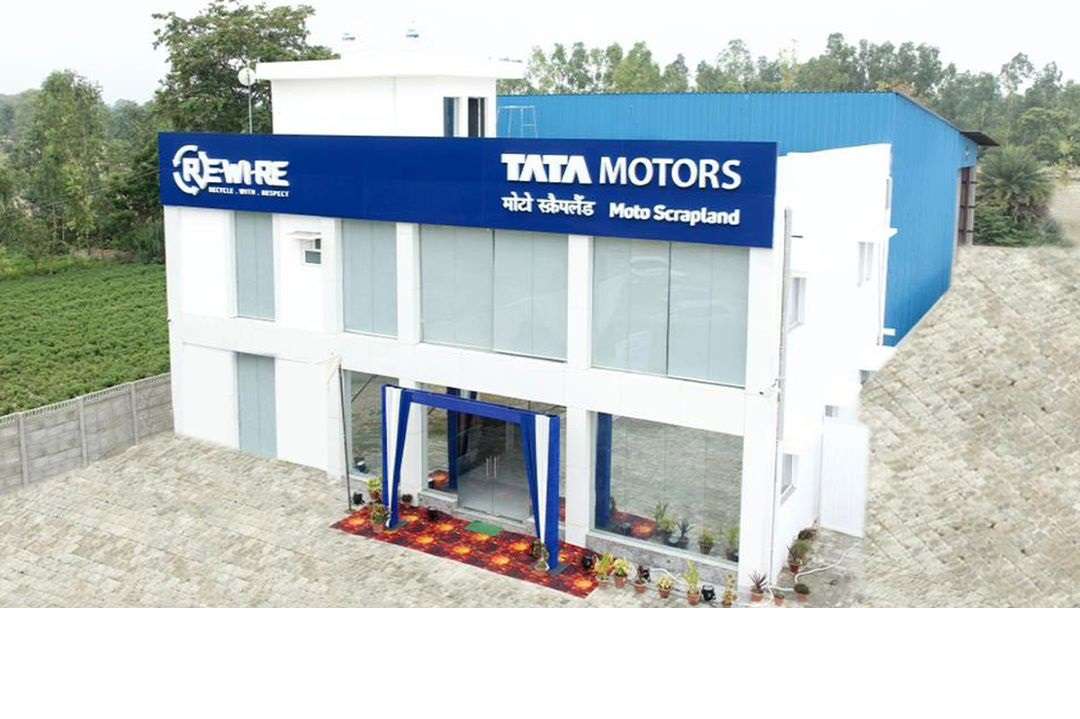

The Raipur facility, operated by Tata Motors’ partner Raipur Green Energy Pvt Ltd, has the capacity to dismantle up to 25,000 vehicles annually, while the Lucknow facility, managed by Moto Scrapland Pvt Ltd, can process up to 15,000 vehicles per year. Girish Wagh, Executive Director of Tata Motors, emphasized the company’s ongoing commitment to sustainability: “At Tata Motors, sustainability is a core pillar that defines our approach to the future of mobility. As part of our Re.Wi.Re initiative, we are on track to responsibly dismantle over 1.75 lakh end-of-life vehicles annually across our expanding network of facilities. This is a crucial step towards realizing the circular economy vision for India.”

With the recent addition of the Lucknow and Raipur centers, Tata Motors now operates a total of 10 vehicle scrapping centers, including those in Jaipur, Bhubaneswar, Surat, Chandigarh, Delhi NCR, Pune, Guwahati, and Kolkata. These facilities are fully digitalized, providing paperless operations and using specialized methods to dismantle vehicles safely and efficiently. The scrapping process involves dedicated stations for the safe removal of tires, batteries, fuels, oils, and gases, ensuring that all components are processed according to the nation’s scrappage policy.

Each Re.Wi.Re facility operates with the latest technology for dismantling vehicles, including cell-type dismantling lines for commercial vehicles and two- and three-wheelers, as well as line-type dismantling for passenger cars. Tata Motors’ innovative approach to vehicle recycling underscores its leadership in sustainable automotive practices. Through its Re.Wi.Re facilities, Tata Motors is setting a new benchmark for vehicle scrapping in India, driving both environmental responsibility and industry progress.