Industrial production is on the brink of a major transformation. Intelligent digital systems are making their way into machine tools, reshaping not only how parts are made but also how equipment is maintained. These technologies are fast becoming the backbone of efficient, environmentally responsible, and competitive production. Amid a shortage of skilled workers and rising global competition, these innovations are no longer optional extras—they are becoming critical to staying in business. Visitors to EMO Hannover 2025, the world’s leading trade fair for production technology, will be able to experience this shift firsthand from September 22–26.

Integrating smart technologies into machine tools goes well beyond conventional automation. These systems can analyze data, make decisions, and continuously improve operations. Advanced sensors, real-time analytics, self-optimizing software, and smart assistance tools are making this possible—both at the machine control level and in collaboration with human operators.

Manufacturing companies are discovering a wide range of possible applications. “A typical use case is the real-time prediction of process characteristics for integrated quality assurance and continuous process monitoring,” explains Prof Philipp Klimant, Head of the Process Digitization and Automation unit at the Fraunhofer IWU in Chemnitz. “The real advantage over traditional monitoring methods lies in the ability to take into account a far larger number of variables,” he adds.

Beyond that, intelligent tools are being used to assist in employee training and support equipment servicing. Fraunhofer IWU, which specializes in adapting machine learning techniques to manufacturing, is led by Martin Dix, Welf-Guntram Drossel, and Steffen Ihlenfeldt—all affiliated with the WGP (German Academic Association for Production Technology). As of January, the WGP has taken over the ProKI initiative—originally funded by Germany’s Ministry of Education and Research—to provide practical guidance and demonstrators, particularly for small and medium-sized enterprises exploring how to adopt these innovations.

Before implementing intelligent technologies, Mr Klimant recommends asking a simple but powerful question: What efficiency gains can realistically be achieved in my production process? The answer, he says, depends on the specific nature of each process. “In some areas like plastics manufacturing—particularly injection molding—defect rates can reach 20 to 30 percent in rare cases. That’s a significant opportunity for improvement.”

Even highly stable processes can benefit, especially in areas like predictive maintenance and extending the lifespan of tools. Mr Klimant adds that these technologies can also help mitigate workforce challenges. “By capturing and storing expertise, smart systems allow for faster training of new hires—especially important as experienced staff retire.”

Mr Klimant, who also teaches virtual technologies at Mittweida University of Applied Sciences, describes the learning systems as tools that “gain insights from data without needing explicit rules or formulas.” For example, in a forming process, an acoustic signal could be analyzed to determine whether a part meets quality standards. These digital tools can integrate with existing control systems to directly influence operations.

For these systems to function effectively, especially in visual inspection, powerful computing hardware is often essential. Mr Klimant explains: “There’s a big difference between training a model and putting it into use. Training is usually done offline and demands far more processing power. For day-to-day operation, simpler edge devices often suffice—unless you’re dealing with image-based tasks, which require more robust computing resources.”

In some cases, real-time performance requirements—like processing results every five seconds versus every thirty—determine the kind of hardware needed. Language-based models, for example, require high-end graphics processors or specialized cards.

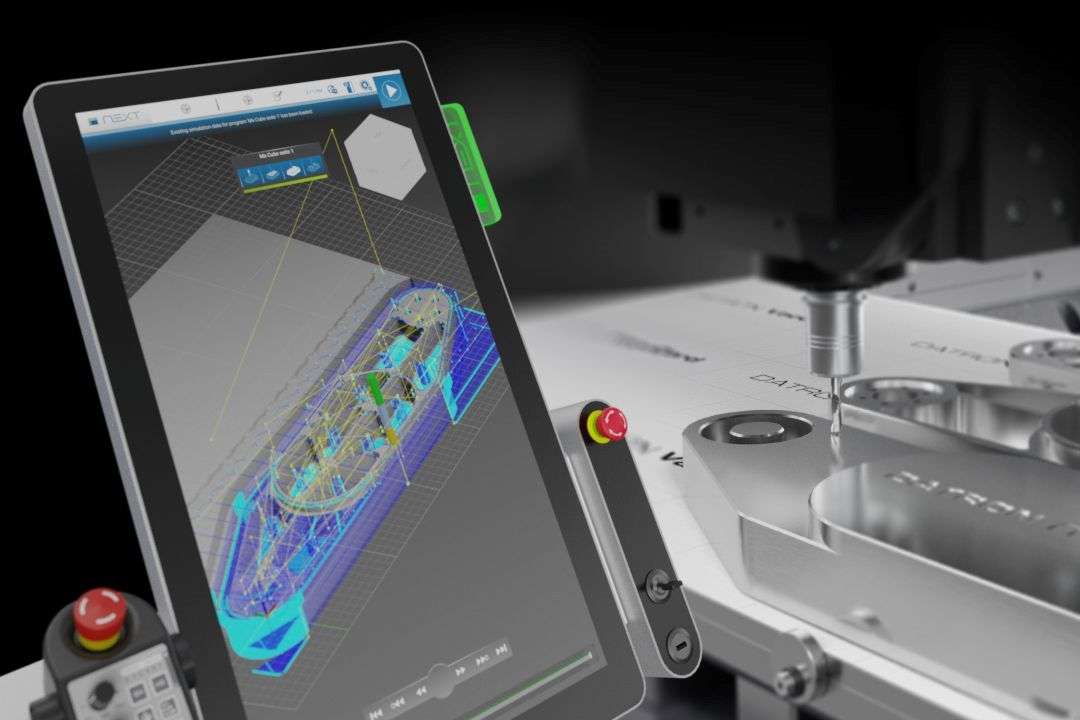

Smart systems are enabling machines to learn and adapt. Datron AG, a milling machine manufacturer based in Ober-Ramstadt, is at the forefront of this shift. Their goal is to create milling machines that adapt on the fly to the specific demands of each part and to changing conditions on the shop floor. “This approach not only shortens set-up and cycle times, but also stabilizes the process—an important step toward autonomous production,” says Jonas Gillmann, the company’s Chief Technology Officer.

Instead of fixed programming, machines are increasingly able to adjust themselves, working in harmony with human operators. “In our field, this isn’t just a future vision—it’s already being implemented,” Mr Gillmann states. With Datron machines, set-up time can be reduced by as much as 60 percent, reject rates fall, tool life is extended, and overall reliability improves.

A standout development is the integration of intelligent features into Datron’s “next” control software. According to Mr Gillmann, this system guides even non-expert users step-by-step through the milling process and can automatically detect workpieces. This reduces the need for specialized knowledge—an advantage in industries struggling with labor shortages. Looking ahead, such tools will support proactive maintenance, enabling operators to fix problems before they occur. “The result is a more flexible, more efficient, and more robust production process,” says Mr Gillmann.

These tools also make it easier to produce custom parts and small batch runs economically. “Smart systems allow for fast changeovers and automated part recognition—without requiring extensive programming,” he explains. This allows one-off or custom components to be produced quickly and cost-effectively, with consistent quality.

The rise of intelligent machine tools is also changing the role of operators. “It’s less about programming and more about managing the process,” says Mr Gillmann. Instead of being programmers, workers become process managers—ensuring quality, fine-tuning parameters, and overseeing operations. “This lowers the learning curve and augments human skills with digital support—not a replacement, but an enhancement.”

Held every two years in a “Hanover–Hanover–Milan” rotation, EMO Hannover will celebrate its 50th anniversary from September 22 to 26, 2025. Under the theme “Innovate Manufacturing,” the event covers the full spectrum of metalworking—from machining and forming systems to software, electronics, and automation.

More than 1,800 exhibitors and 92,000 visitors attended the last event in 2023. Companies and experts from over 45 countries—spanning industries from aerospace and automotive to medical technology and shipbuilding—come to EMO to exchange ideas, explore emerging trends, and shape the future of manufacturing. As a showcase for advanced production solutions, EMO remains the go-to platform for innovation, knowledge-sharing, and global collaboration.