Epsilon Advanced Materials, a leading manufacturer of battery materials, is ready to form long-term strategic partnerships with companies seeking to source high-quality graphite anode and cathode materials outside of China, according to the company’s Managing Director. Electric vehicle (EV) batteries are composed of several key components, including anode, cathode, electrolyte, and separator.

China currently dominates the global market, controlling more than 90% of the processing capacity for graphite anodes and cathodes used in EV batteries. However, recent Chinese restrictions on the export of critical battery materials and technologies, including graphite and lithium iron phosphate (LFP)-based cathodes, have raised concerns about supply chain vulnerabilities across the global EV sector, particularly in India. In response to these challenges, India is actively working to build a more resilient, localized battery supply chain, spurred by China’s tightening export controls on essential battery technologies.

“Epsilon is ready to collaborate with cell manufacturers and auto OEMs who are looking for alternatives to China to secure a stable, long-term supply of high-quality anode materials and LFP cathodes while advancing their localization and sustainability goals,” said Vikram Handa, Managing Director of Epsilon, in a recent interview.

China’s early dominance in the global battery materials sector has given it a significant competitive advantage for decades. However, recent export restrictions have highlighted the importance for battery manufacturers and automotive OEMs to diversify their sourcing beyond China.

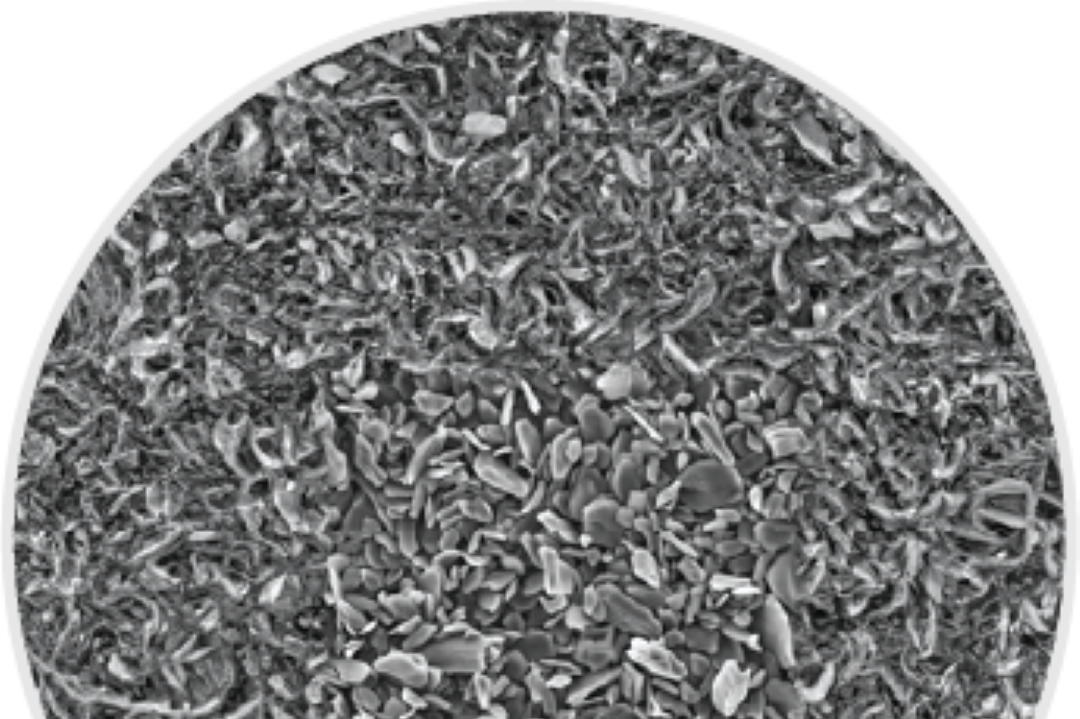

“Our proprietary blend of synthetic and natural graphite anode materials ensures a secure, consistent supply chain for customers worldwide. We’ve also made substantial investments in our R&D facilities and commercial plants to provide our customers with the necessary samples for testing and qualification,” Mr Handa added.

Epsilon’s proprietary technology for manufacturing lithium iron phosphate (LFP) cathodes, backed by an R&D facility in Germany, shields the company from the impact of China’s export curbs. Many companies that relied on Chinese LFP technology for manufacturing in India are now facing delays and may need to invest in their own R&D, a process that typically takes 5 to 6 years to mature.

With manufacturing plants located in India, the USA, and Finland, Epsilon is poised to become the largest producer of anode materials outside China, with a production capacity of 60,000 tons by 2027 and 220,000 tons by 2030. This will further strengthen the company’s supply chain resilience.

“By establishing a cathode material plant in India with a capacity of 100,000 tons by 2030, we aim to achieve self-sufficiency in the EV battery material supply chain, positioning ourselves as a key player in India’s growing electric vehicle market. Our international presence offers customers more flexibility, localized supply options, and reduces the risk of supply disruptions,” Mr Handa explained.

Epsilon is also investing Rs 15,350 crore in Karnataka to develop a state-of-the-art facility for manufacturing electric vehicle battery materials, battery testing, and advanced materials research and development. Founded in 2010, Epsilon Group is involved in the carbon and battery materials sector through subsidiaries like Epsilon Carbon and Epsilon Advanced Materials.

Epsilon Carbon operates India’s first integrated carbon complex in Karnataka, while EAM, launched in 2018, produces anode and cathode materials for lithium-ion batteries with ongoing operations in India, the U.S., and Finland. The group is also actively entering the LFP-based cathode material segment to cater to the growing global demand for battery solutions.

Epsilon Advanced Materials is known for its expertise in materials science, offering advanced solutions such as semiconductor materials, energy storage technologies, and specialty coatings. With a commitment to research and development, the company aims to drive innovation and contribute to the growth of industries that require high-quality, specialized materials for next-generation applications.