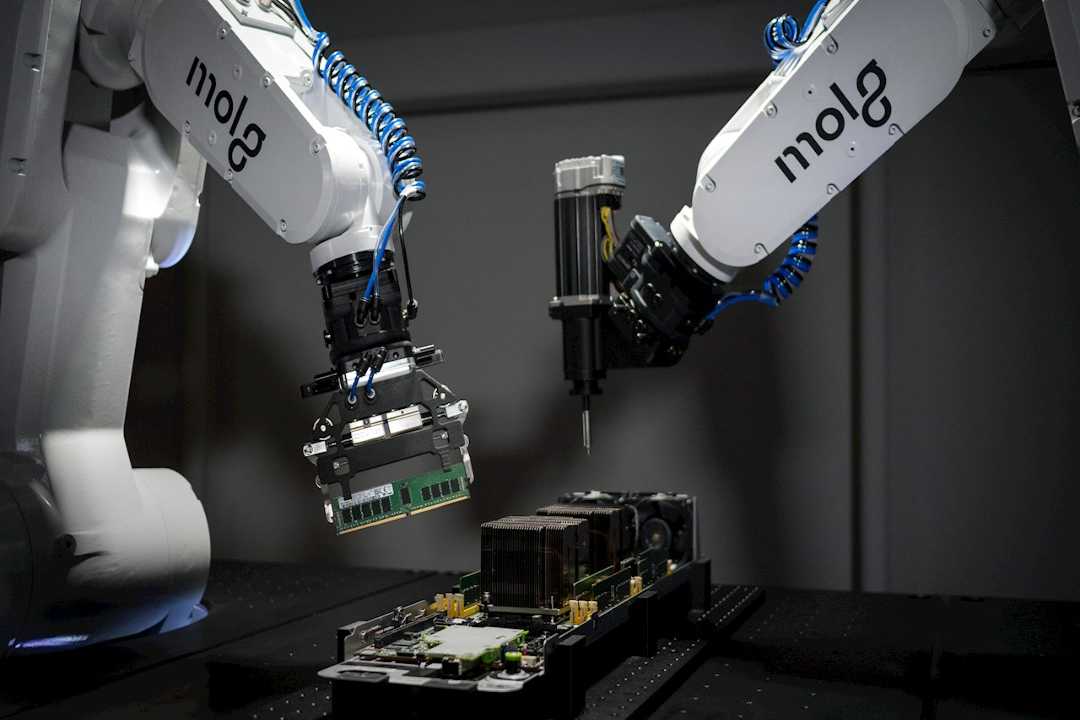

ABB Motion’s Drive Products division has entered into a strategic partnership with Molg, a Virginia-based circular manufacturing company, through its ABB Motion Ventures unit. This investment will focus on optimizing the design and reusability of ABB drives. The collaboration aims to streamline manufacturing operations by incorporating Molg’s design expertise and innovative robotic Microfactories, enhancing assembly and testing processes while boosting resource efficiency and drive circularity.

ABB’s partnership with Molg began in 2023 when Molg won the ABB Accelerating Circularity Startup Challenge. Since then, the two companies have successfully developed a proof of concept for drive assembly using Molg’s robotics-based Microfactories. This new investment will propel the next stage of their collaboration.

A key factor behind ABB’s decision to invest in Molg is the company’s strong commitment to circularity. ABB has set a target to adopt a full life cycle circular approach for 80% of its products by 2030. Molg’s robotic Microfactories will enhance the efficiency of customized drives by automating assembly and testing processes. This investment further solidifies ABB’s role as a driving force in the circular economy by emphasizing the reuse, repurposing, and recycling of components. In October 2024, ABB Robotics & Automation Ventures also participated in Molg’s seed funding round to scale production and address e-waste issues with advanced robotics and design solutions.

This partnership aligns with ABB’s broader strategy of local manufacturing. It follows ABB’s recent $100 million campus project in New Berlin, Wisconsin, and strengthens its ‘local for local’ approach, which prioritizes sourcing materials locally for in-country manufacturing to better serve regional customers. This initiative is a crucial element of ABB’s circularity-driven model, which aims to minimize waste and reduce carbon emissions from manufacturing, while also supporting local supply chains.

TuomoHoysniemi, President of ABB Drive Products Division, expressed, “Our investment in Molg places us at the heart of an innovation ecosystem focused on circularity. This partnership enhances our drive portfolio through the recycling and reuse of components, aligning with our circularity goals. Molg’sMicrofactories, tailored for ABB’s customizable product range, offer a unique ability to meet future market and customer needs while preserving valuable resources.”

Molg CEO and Co-Founder Rob Lawson-Shanks shared, “Winning ABB’s Accelerating Circularity Startup Challenge was a significant milestone for us. We’re excited to continue working with ABB to design more circular products and create manufacturing processes that promote sustainability, improve supply chain resilience, and keep valuable materials in circulation.”

ABB is a global leader in electrification and automation, committed to driving a more sustainable, resource-efficient future. With over 140 years of history and a workforce of approximately 110,000 employees worldwide, ABB is listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB).

ABB Motion Ventures, the company’s venture capital arm, seeks breakthrough technologies that align with ABB’s mission of shaping the future of industrial electrification and automation. Since its establishment in 2009, ABB Ventures has invested approximately $500 million in startups across various sectors, including robotics, industrial IoT, AI, energy transition, cybersecurity, and electric mobility.

Molg is addressing the growing issue of e-waste by promoting circular manufacturing. Its robotic Microfactory autonomously disassembles complex electronics like laptops and servers, recovering valuable components and materials for reuse. Molg collaborates with leading electronics manufacturers to design next-generation products with reuse in mind, ensuring that a product’s end marks the beginning of another’s lifecycle.