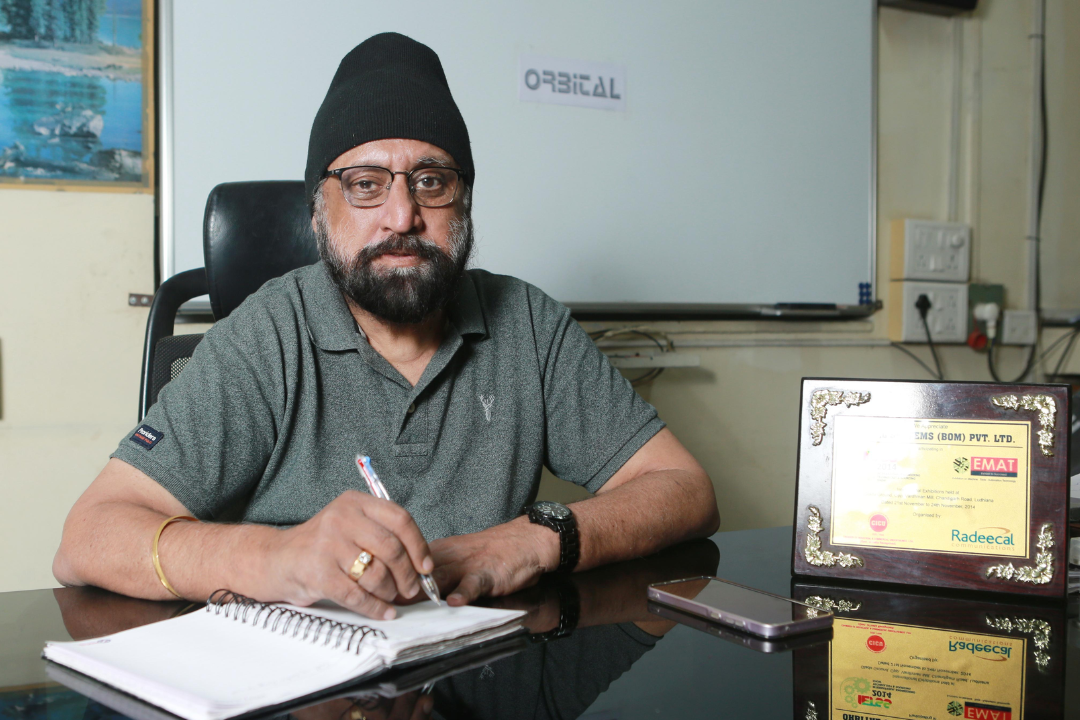

Paramjit Singh Sehra founder, Managing Director established Orbital Systems, one of the leading companies that has been at the pioneering of India’s manufacturing since 1985. With its roots in mechanical engineering, the company began its journey in Mumbai and relocated to Nashik in 1988.

Over the past 36 years, Orbital Systems has built a reputation as a leader in assembly automation, catering to a wide range of industries with innovative and cost-effective solutions. One of the key philosophies driving Orbital Systems is ensuring every machine acts as a “salesman”. This approach emphasizes delivering quality products and robust after-sales service. The company’s customer-centric strategy includes encouraging potential buyers to consult existing users of Orbital’s products, thereby fostering trust and transparency in its operations.

Orbital Systems was founded with a clear objective: to create import-substituted products and save valuable foreign exchange for India. The company’s first milestone was the development of riveting machines, which eliminated the need for Indian manufacturers to import these machines from Japan. Building on this success, Orbital Systems introduced indexing tables, automatic screw fitment machines, and clinching machines, enabling industries to enhance productivity while reducing reliance on manual labor.

Global Connections, Trusted Collaborations

Orbital Systems’ commitment to quality has earned its clients across the United States, Europe, and the Middle East. The company also manufactures machines for leading US based brands, adhering to their designs and delivering unmatched precision and reliability. Remarkably, Orbital has maintained a 27-year-long partnership with some of these companies without requiring them to visit its facilities in India, an enduring testament to the trust and quality Orbital provides.

A standout project for Havells epitomizes the company’s problem-solving capabilities. Many of the companies needed to assemble fans in just four seconds but faced bottlenecks in screw fitment. Orbital Systems reduced the task requiring six operators to just one, completing it in 3.85 seconds saving time, manpower, and resources. This success highlights Orbital Systems’ ability to engineer innovative, customized automation solutions.

Looking ahead, Mr Sehra envisions growth through strategic joint ventures. He believes partnering with global companies can accelerate innovation and scale. A joint venture would allow Orbital Systems to access pre-existing designs for faster development and offer partners cost advantages through manufacturing in India. “If we can jointly design and manufacture, the cost advantage in their home country would be tremendous” he explains.

As demand for assembly automation grows, Orbital Systems aims to expand its footprint through joint ventures with global partners. By leveraging its expertise in manufacturing and the design capabilities of potential collaborators, the company envisions creating a seamless blend of innovation and cost-efficiency, positioning itself as a global hub for assembly automation solutions.