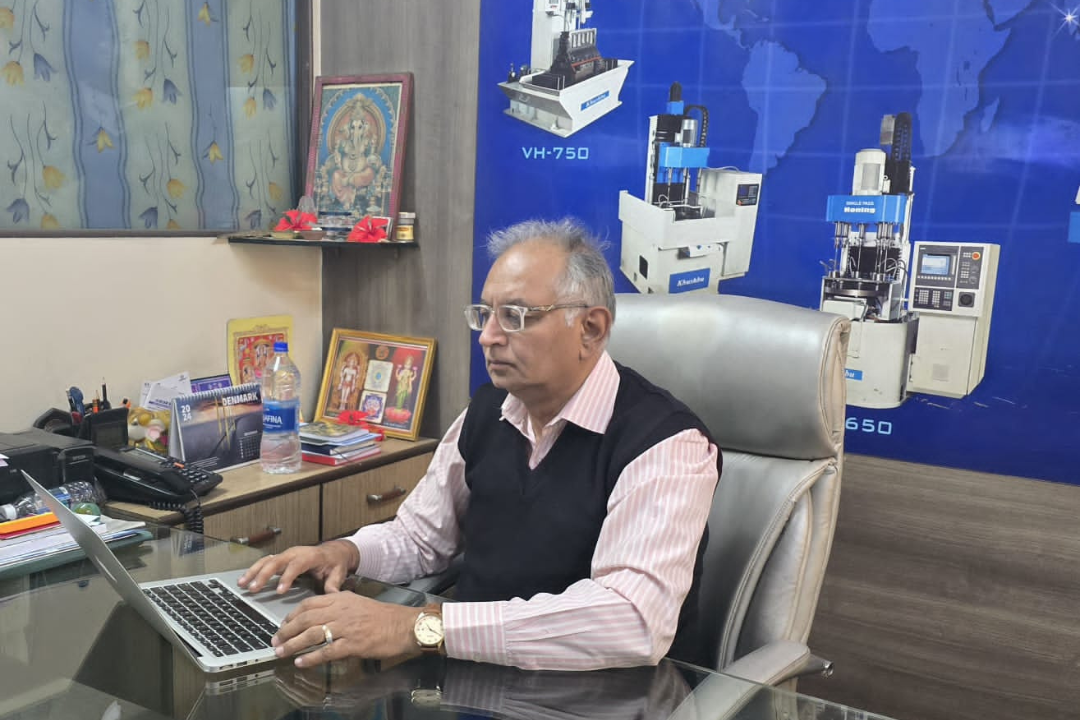

Ajit Samani, Founder and Managing Director of Khushbu Honing Pvt Ltd, established the company in 1994 with a focus on developing honing machines for the manufacturing industry. From his experience in the machine tool sector since 1988, he started with basic manual and auto-stroking machines before advancing to CNC and multi-spindle progressive honing machines. Under his leadership, Khushbu Honing has grown into one of the trusted providers of high-accuracy, high-productivity solutions for both domestic and international markets.

Established in 1994, Khusbhu Honing Machines has grown from a medium operation to one of the key players in the honing machine industry. The company, founded by AjitSamani, began with basic manual auto-stroking machines and gradually advanced its offerings to hydraulic vertical, CNC, and CNC multi-spindle honing machines. Nowadays, Khusbhu Honing is known for its CNC multi-spindle progressive honing machines, which prioritize high accuracy and high productivity, a much-needed alternative to imported machinery in India.

The primary objective behind establishing Khushbu Honing was to offer an option for high-quality bore finishing machines. Initially, the focus was on manual and auto-stroking machines that offered low production rates and moderate accuracy. Over time, the demand for precision and efficiency grew, and they responded by developing CNC and multi-spindle progressive honing machines. These machines allowed manufacturers to achieve higher production rates and greater accuracy, addressing a gap in the domestic market that was previously filled by imported machines.

Today, Khushbu Honing’s machines are exported to regions like Europe, the Middle East, China, and Turkey. The company’s ability to produce reliable, cost-effective machines has contributed to its growth as a competitive player on the global stage. “Back then, only imported machines could deliver the kind of productivity and accuracy that customers demanded,” Mr Samani recalls. “By 2000, we were manufacturing CNC multi-spindle progressive honing machines, which helped Indian manufacturers reduce their reliance on imports.”

According to Ajit, the initial hurdles included hiring skilled labor, securing finance, establishing customer relationships, and managing operational costs. “You need all these elements to come together,” he explains. “Otherwise, it becomes difficult.” The breakthrough came when the company built its first honing machine for internal use to produce jig bushes. The machine’s success caught the attention of other manufacturers, who began requesting similar machines. This led to the company’s gradual entry into the wider market. “It was a slow but steady development, but it was good development, he notes.

Made in India, A Look Ahead at What’s Next

Khushbu Honing’s focus is on maintaining quality and reliability. Customer demand for repeat orders has increased, and the company’s current priority is to fulfill those orders while maintaining high standards. Ajit shares that they’re focusing on supplying high-quality, reliable machines to existing and new customers, and service support is an area where they’re strengthening their resources by hiring new people. While new product development has slowed down, the company’s goal is clear: to provide effective, customer-centric solutions that support production growth and deliver consistent accuracy. “Customer satisfaction remains our core objective,” he emphasizes.

One of Khusbhu’s standout qualities is its ability to deliver both high productivity and high accuracy, a challenge for many honing machine manufacturers. Before Khusbhu Honing’s introduction of CNC machines, customers were producing around 500 parts per day. Today, with their CNC multi-spindle machines, production rates have soared to 10,000 parts per day with an accuracy of just 2 microns. “That’s our USP, high productivity combined with high accuracy,” says Mr Samani. “It’s what sets us apart in the market.”

The “Make in India” initiative has been a welcome move for Khusbhu Honing and other domestic manufacturers. Mr Samani highlights that the initiative aligns with the company’s long-standing approach of making import substitutes. “We’ve been doing ‘Make in India’ since 1994,” he says. “Back then, we focused on import substitution by developing CNC honing machines locally.” He believes that the Indian government’s current policies are more industry-friendly and supportive than ever before. “The government’s policies now encourage growth and support manufacturers like us. It’s a positive step forward for the industry,” he adds.

He then shares his message to the industry in a straightforward way: Indian manufacturers are just as capable as their global counterparts, and Indian machines are on par with imported equipment in terms of quality and performance, but they’re available at a much lower cost. He also emphasizes the role Indian manufacturers can play in saving valuable foreign exchange and supporting the local economy. By choosing domestic products, manufacturers can reduce reliance on imports and contribute to India’s industrial growth.

As Khusbhu Honing Machines moves forward, it continues to uphold its promise of providing precise, high-performance honing solutions to manufacturers worldwide. By focusing on quality, service, and customer satisfaction, the company aims to remain a vital part of India’s journey toward self-reliance and manufacturing excellence.