Aerotech, a global leader in precision motion control and automation, announced the release of its groundbreaking DrillOptimizer, an advanced AeroScriptPlus feature for galvo scanner systems. Designed for equipment manufacturers using laser drilling with high-dynamic point-to-point motion, DrillOptimizer tackles the complex challenge of optimising step and settle motion for thousands to millions of hole locations, minimising overall drilling cycle time and maximising galvo scanner hardware performance.

Aerotech has unveiled DrillOptimizer, a powerful new AeroScriptPlus feature developed to enhance laser drilling performance in galvo scanner systems dramatically. Tailored for equipment manufacturers performing high-dynamic point-to-point laser drilling across thousands to millions of holes, DrillOptimizer intelligently minimizes overall drilling cycle time while ensuring uncompromised precision.

“Optimising high-dynamic point-to-point motion for laser drilling applications with varying hole distances has long been demanding,” says Aerotech Product Manager Bryan Germann. “We created DrillOptimizer so our customers can save development time and increase throughput without sacrificing precision.”

DrillOptimizer works in two key ways:

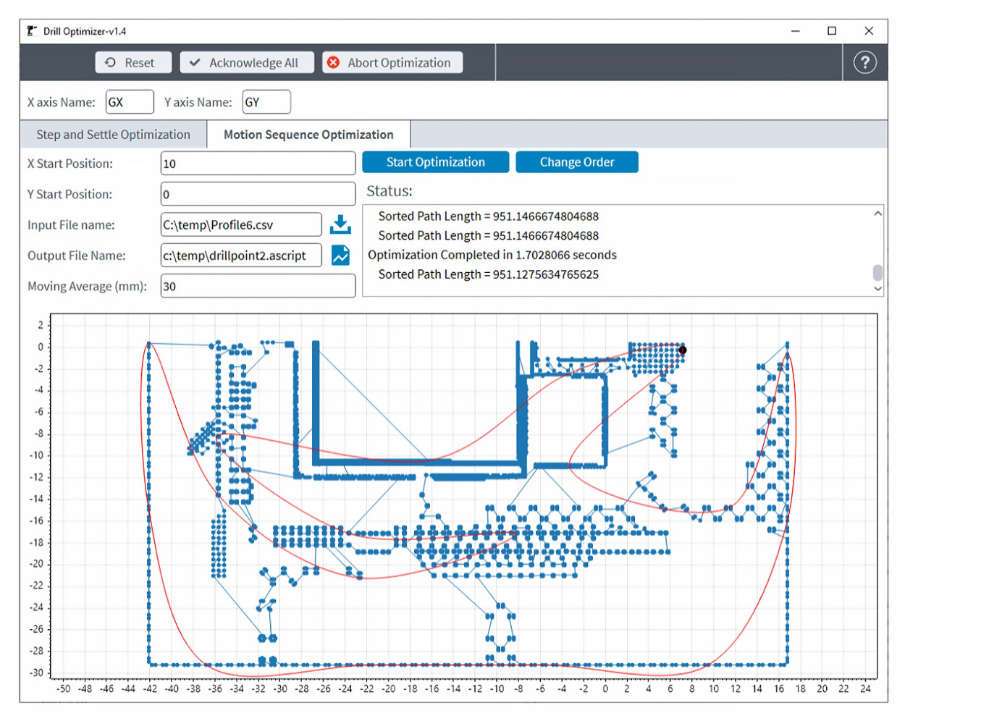

- Motion Sequence Optimisation: DrillOptimizer intelligently determines the most efficient path through a pattern of holes within a single scanner field of view (FOV) or when combined with a servo stage system using Infinite Field of View (IFOV). This path optimisation directly minimises the overall cycle time by ensuring the shortest travel distance for the scanner.

- Step and Settle Optimisation: DrillOptimizer enables optimal controller parameters for any specific step distance without the scanner leaving the user-defined settle window. By identifying the ideal parameters for each move based on the user-specified settle window and laser-on time, settling move delays are eliminated, allowing the laser to fire with zero delay if the scanner remains within the settle window.

Key benefits of DrillOptimizer include significantly reduced cycle times through intelligent motion path optimisation and enhanced galvo scanner hardware performance for every move. The system ensures seamless operation and maximised throughput by eliminating delays between scanner positioning and laser firing. It guarantees high precision even in large-scale drilling applications, making it ideal for demanding production environments.

The intuitive Windows-based user interface accelerates process development, while seamless integration into custom machine HMIs is enabled via a .NET DLL. DrillOptimizer delivers production-scale performance with minimal setup required and is fully compatible with Aerotech’s AGV series galvo laser scan heads, including the AGV-HPO and AGV-XPO models.

Since 1970, Aerotech Inc has been a global leader in precision motion control and automation, delivering innovative solutions that power some of the world’s most advanced technologies. From standard positioning equipment and control systems to fully customised automation platforms, Aerotech’s products serve the demanding needs of research institutions and industrial manufacturers worldwide. Their high-performance solutions enable ultra-precise manufacturing, testing, and inspection at micrometre and nanometer scales, supporting top-tier companies across aerospace, consumer electronics, medical devices, and other high-tech industries.