In 2011, Wohlhaupter India was incorporated as a subsidiary of Wohlhaupter GmbH, a world leader in precision boring tools established in 1929. Allied Machine and Engineering acquired the majority share of Wohlhaupter in 2016 to expand their holemaking and hole finishing solutions and offer support worldwide. At IMTEX 2025, Wohlhaupter India will showcase a wide range of holemaking and hole finishing cutting tools, custom tool design services and expert application support for the metal-cutting industry.

Wohlhaupter India Private Limited provides expert engineering, technical support and onsite application services within India for Wohlhaupter GmbH and Allied Machine and Engineering Corp., leading manufacturers of holemaking and finishing tooling systems for the manufacturing industry. The company is highlighting a variety of cutting tools at IMTEX, including T-A Pro high penetration replaceable insert drill, Wohlhaupter boring tools and thread mills.

The T-A Pro drilling system provides extended tool life, consistently creates quality holes and delivers superior chip evacuation even in the toughest applications. The drill body incorporates straight flutes designed for maximum coolant flow and excellent rigidity, while the material-specific insert geometries produce impeccable chip formation. These insert geometries include:

- Steel (P) with AM300 coating.

- Cast iron (K) with TiAIN coating.

- Nonferrous (N) with TiCN coating.

- Stainless steel (M) with AM460 coating.

- High-speed steel substrate (X) with AM200 coating.

The newest addition to the T-A Pro drilling system is the Y series, which upgrades manufacturing processes, allows machinists to increase throughput in their cutting tool applications and ultimately allows users to experience the benefits of the T-A Pro line at smaller diameters. Available in stub to 15xD and ISO-specific carbide grades P, K, and N as well as high-speed steel substrate X, T-A Pro Y series has a diameter range of 9.50 millimeters – 11.09 millimeters (0.3739 inches – 0.4368 inches).

With exchangeable tips and the ability to target specific materials and applications with an ISO-specific geometry selection on a single holder body, the T-A Pro Y series gives machine shops the opportunity to upgrade to a superior system. This allows them to increase penetration rates, maximize tool life, and take advantage of a more favorable cost per hole.

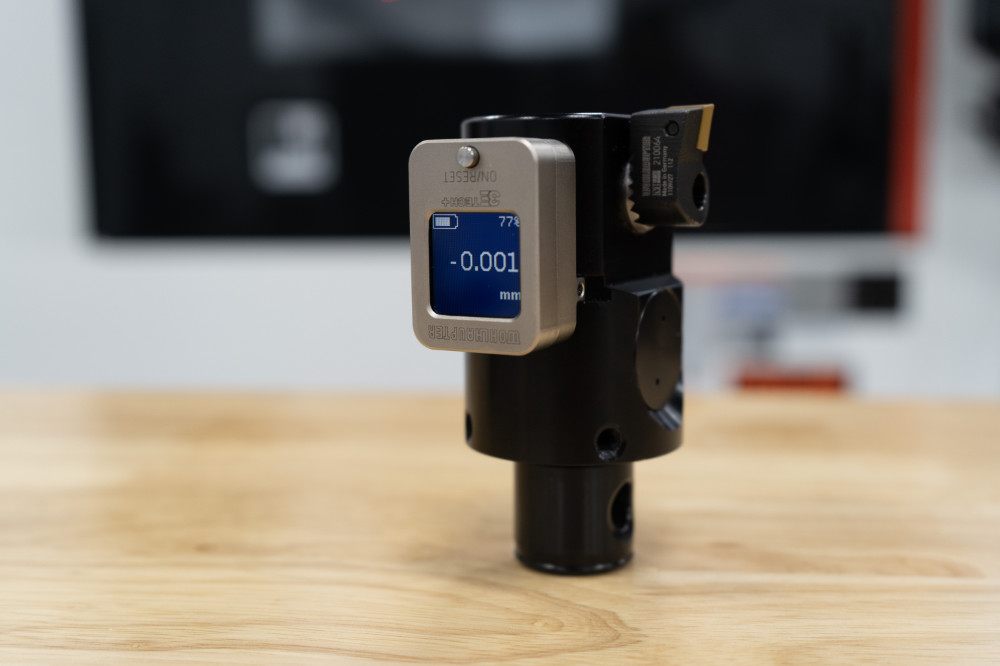

Wohlhaupter’s 3ETECH+ digitalreadout module is ideal for machinists looking to make diameter adjustments right at the machine, providing unmatched ease of use. With premium visibility of one-micron diameter adjustments, precision boring is easier than ever. High-production environments such as aerospace, heavy equipment, and automotive greatly benefit from the enhanced digital readout module, which can be used for various Wohlhaupter boring tools. Having an external, removable digital module also eliminates the worry of costly digital tooling components being harmed by cutting chips or high-pressure coolant.

Wohlhaupter’s ES-Bore fine boring lay down cartridge is just one of the many tools that provides 3ETECH+ functionality while having an analog version. ES-Bore lay down cartridges can easily be mounted onto the body of a custom tool while the dimensions allow the cartridge to fit on existing bodies and replace current lay down cartridges. When used with standard Wohlhaupter components, the lay down cartridges have a diameter range of 28 millimeters – 3200 millimeters (1.1 inches – 128 inches); however, a maximum boring range cannot be defined for custom boring tools as the range is unlimited and depends on the application.

These cartridges provide the possibility to design custom tools incorporating the ES-Bore lay down cartridges, allowing customers to receive special tools within a shorter delivery time and at a lower cost. Additionally, the fine boring cartridges give customers the opportunity to build their own special tool because the customer only needs an ES-Bore lay down cartridge that can be mounted onto the boring bar being manufactured.

Allied Machine’s thread milling product line is a comprehensive range of high-precision tooling that offers outstanding productivity with exceptional levels of tool life and thread accuracy. Specifically designed to provide customers with a wide range of options, the thread mill range covers both solid carbide and indexable replaceable insert tools with an extensive range of thread forms. Two thread mill ranges are available within the product lineup: the general production ThreadMills USA range and the high performance, high productivity AccuThread range.

Known for producing high-quality thread mills, ThreadMills USA is an economic thread milling product backed by Allied’s experienced technical staff and provides quality threads when compared to other thread making processes. Not only can one tool cut right- and left-hand threads, but the standard cutting lengths available accommodate multiple applications without the need for an engineered special.

AccuThread 856 solid carbide thread mills yield a 25-50% increase in tool life over other thread mills on the market while also providing increased strength and rigidity when cutting forces are applied due to the helical flute.

Designed to machine just three threads at a time, the AccuThread T3 thread mill is built for machining hardened or difficult-to-machine materials such as stainless steel, tool steel, and high-temp alloys. In addition to providing reduced tool pressure and superior thread quality in tough materials, the T3 offers longer tool life, less tool breakage and higher quality threads for machinists.

Headquartered in Delhi, Wohlhaupter India offers a large team of field support engineers nationwide to provide application support and find the most efficient economical drilling, reaming, boring, threading, porting and custom tooling solutions. Established in 1929, Wohlhaupter continues to manufacture the most comprehensive range of precision boring tools and systems available in the marketplace and has been the consistent leader in technological innovations for improving precision boring operations. In 2016, Allied Machine and Engineering purchased the majority shares of Wohlhaupter. Allied Machine and Engineering and Wohlhaupter provide precision engineering and expert application support to provide cost-effective holemaking and finishing solutions for today’s manufacturers worldwide.

Allied Machine & Engineering is a leading manufacturer of holemaking and hole finishing tooling systems. It devotes its advanced engineering and manufacturing capabilities to creating the widest selection of value-added tooling available to metal-cutting industries worldwide. Their tooling solutions deliver the lowest cost per hole in a wide range of drilling, reaming, threading, boring, and burnishing applications. Located in Dover, Ohio, USA, Allied’s precision holemaking technologies provide end users worldwide with the highest level of drill performance. Precision engineering and expert application support make Allied the first and best choice for solving complex metal-cutting challenges.

To learn more about Allied Machine’s holemaking and hole finish-cutting tool solutions, visit the IMTEX 2025 exhibition organised by the India Machine Tool Manufacturers’ Association at Bangalore International Exhibition Centre from 23-29 January 2025. For more details about Allied Machine’s wide range of products and innovations, visit www.alliedmachine.com.