Leanworx, a forward-thinking company operating under the parent company, Cadem, has been at the forefront of transforming machine productivity in the manufacturing sector. Founded in 2016, Leanworx leverages the principles of Industry 4.0 to enhance the efficiency of metal-cutting machines by linking them with operators and providing real-time data. The founders, led by Srihari D, have dedicated their efforts to bridging the gap between machines and humans, ensuring that every operation in the manufacturing process runs smoothly and efficiently.

As the company gears up for its second participation in ALUCAST 2024, the largest platform for die-casting and allied industries, Leanworx is set to showcase its cutting-edge solutions to increase the productivity of expensive die-casting machines. By providing instantaneous, accurate data from machines, the company enables decision-makers to take decisive action, making it an essential tool for any manufacturing firm aiming to stay competitive in the era of Industry 4.0.

Revolutionizing Machine Monitoring Systems for Industry 4.0

The backbone of Leanworx’s success lies in its machine monitoring system, designed to provide accurate and real-time insights that reduce waste in machine capacity, materials, and manpower. The founders recognized that traditional monitoring systems often suffer from inaccuracies and delays, with decision-makers receiving outdated data—sometimes up to 48 hours after a crisis occurs. To tackle this challenge, Leanworx developed an automated system based on Industry 4.0, which eliminates the inefficiencies associated with manual data collection.

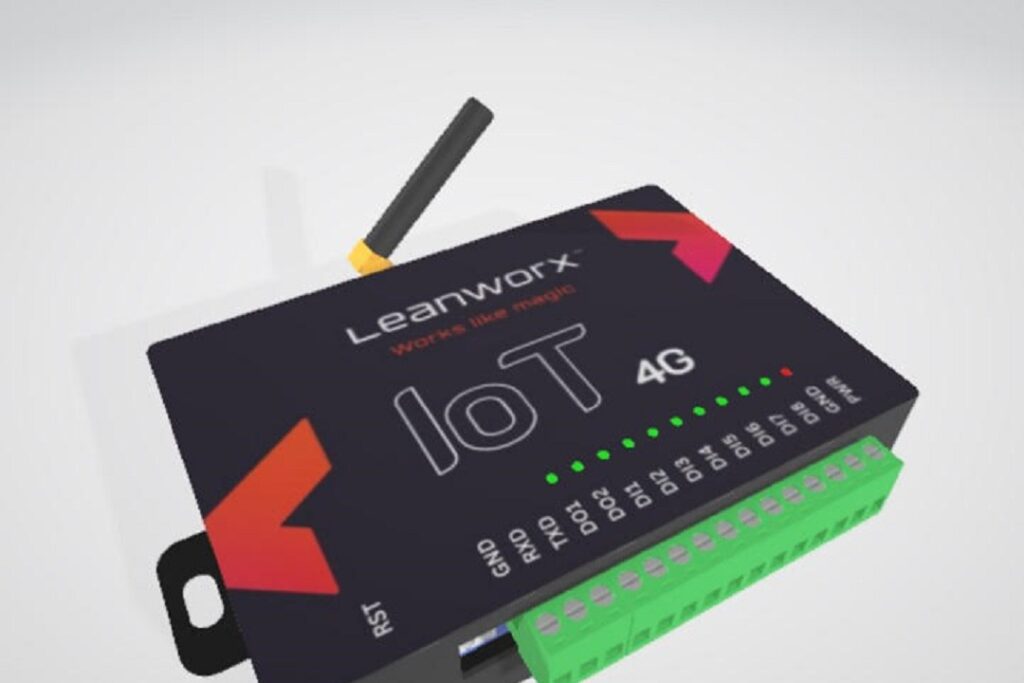

The company’s flagship system provides an array of essential functions, including downtime tracking, OEE (Overall Equipment Effectiveness) monitoring, and production tracking, all delivered through a user-friendly interface. Leanworx’s solution is cost-effective and adaptable, suitable for machines of any age, electronics level, or process type. Whether it’s a legacy machine or a cutting-edge CNC tool, Leanworx ensures that the system can integrate seamlessly, providing real-time data that allows for more informed decision-making.

One of Leanworx’s key philosophies is embodied in its TRUMP formula, which emphasizes Tamper-proof data, Reliability, Universal interface, Maintenance ease, and Productivity enhancement. These principles guide every product the company develops, ensuring that its systems are not only efficient but also secure and scalable for the future of manufacturing.

As Leanworx returns for its second participation in ALUCAST 2024, the company is eager to introduce its latest advancements tailored to the die-casting industry. With die-casting machines being high-cost investments, ensuring their optimal performance is paramount for manufacturers. Leanworx addresses this by offering advanced machine monitoring systems that provide actionable insights, allowing companies to trust the data their machines generate and make data-driven decisions that improve productivity and reduce capital expenditure (CapEx).

A unique feature of Leanworx’s offering is its Android-based touchboard, which allows operators to perform machine operations and monitor performance in real time. This interactive system provides visual feedback and insights, ensuring that data-related debates within companies become a thing of the past. With this system, manufacturers can confidently assess machine performance and make decisions that lead to productivity improvements and more efficient use of resources.

The system also enables online monitoring, giving manufacturers access to machine data from anywhere worldwide. This is particularly advantageous for companies looking to optimize their global operations and ensure consistent performance across various locations.

Since its inception, Leanworx has made remarkable strides in the machine monitoring landscape. In just eight months of operation, Leanworx secured the prestigious FIE Foundation award at IMTEX 2018, a testament to its innovative approach to boosting machine efficiency.

Today, Leanworx serves a diverse clientele, ranging from small shops with seven machines to large corporations in the automotive, aerospace, and tooling industries. The company’s mission to “empower discrete manufacturing shop floors to go Lean” aligns with its vision to provide affordable, plug-and-play solutions that facilitate greater productivity. With associations abroad and a growing presence in India’s top manufacturing industries, Leanworx continues to cement its position as a leader in Industry 4.0 solutions.

At ALUCAST 2024, Leanworx will showcase its innovations in Hall 2, Stall A9. Visitors can expect live demonstrations of its IoT devices and machine monitoring solutions, further solidifying the company’s commitment to advancing die-casting technology and improving global manufacturing competitiveness.