ABB has introduced an innovative low-force system designed for cold rolling mills, specifically tailored for producing ultra-thin metal strips such as aluminum, copper, and steel foils. The new Stressometer Low-Force Flatness System combines precision, durability, and cost efficiency for superior metal processing.

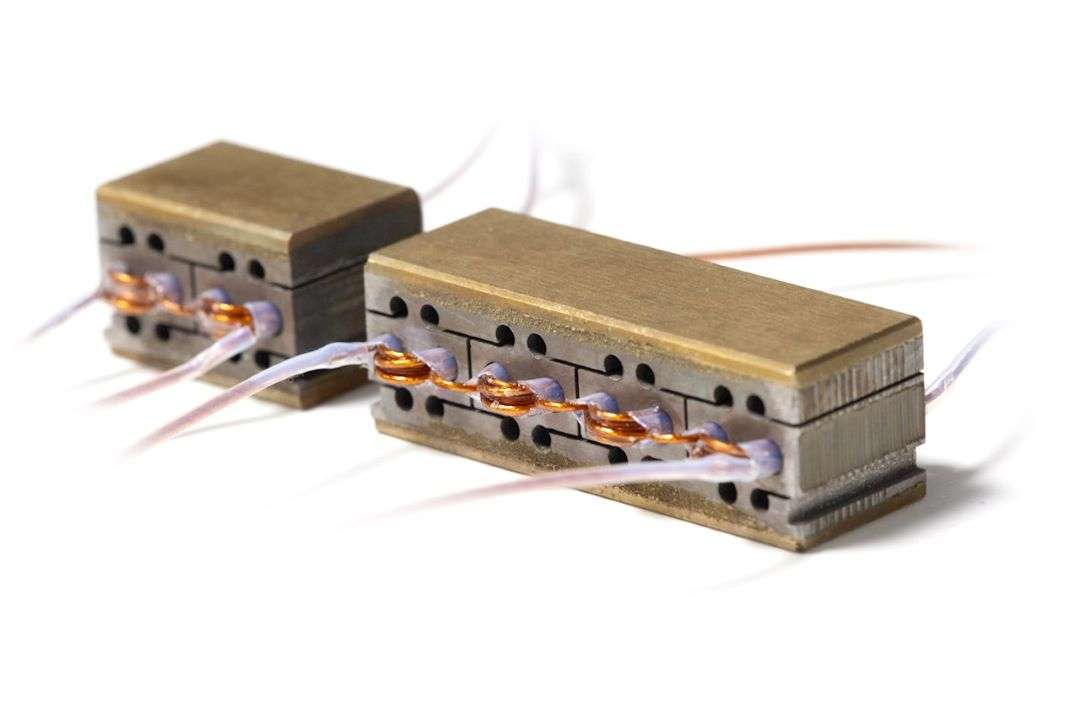

This system is housed in a compact 200 mm diameter roll, maintaining the same physical size as ABB’s standard Stressometer® sensor. It incorporates advanced material properties that can detect minute variations in force with remarkable accuracy, down to just a few grams. This ensures tighter control of flatness, thickness, and tension for finishing processes handling foil gauges ranging from 50 to 5 microns.

The Stressometer Low-Force Flatness System is ideal for finishing mills and integrated lines processing both breakdown and finishing passes. Its high performance provides precise control, especially in applications where traditional force sensors may struggle, particularly for thicknesses under 20 microns. This reliability reduces scrap and re-processing, helping manufacturers maintain high throughput and consistent quality.

Marko Sydanlammi, Global Portfolio Manager for Force Measurement at ABB’s Measurement & Analytics division, commented, “Our new low-force system answers the demand for solutions that enhance quality, yield, and energy efficiency in metal production, even in the most challenging foil applications. It provides the durability and cost efficiency needed to meet these challenges.”

The need for ultra-thin metals is increasing as industries such as electronics, automotive, aerospace, and medical device manufacturing push for smaller, lighter, and stronger components. The low-force system offers improved control over cold rolling processes, ensuring precise production to meet stringent specifications.

Unlike other sensor technologies, ABB’s low-force system is built with a robust mechanical design that minimizes utility requirements and virtually eliminates wear-related maintenance. This results in better performance and stability under temperature fluctuations, along with energy savings by reducing compressed air consumption.

The system’s capabilities have been successfully validated in pilot projects, including EV battery production in South Korea and specialty foil mills in Europe and Asia. With its extended measurement range tailored to foil applications, the new system strengthens ABB’s portfolio, reinforcing the company’s commitment to helping industries operate more efficiently and sustainably.

ABB is a global leader in electrification and automation, focused on creating a more sustainable and resource-efficient future. By combining engineering and digitalization expertise, ABB helps industries operate at peak performance while improving efficiency, productivity, and sustainability. With over 140 years of history, the company employs around 110,000 people worldwide and is listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB).

ABB’s Process Automation division specializes in automating, electrifying, and digitalizing industrial operations across key sectors, including energy, water, materials, and manufacturing. With approximately 20,000 employees, ABB Process Automation leads the way in helping industries become leaner, cleaner, and more efficient.