CloudNC, a leader in advanced manufacturing technology, has announced that its Soft Jaw Designer plug-in is now available at no cost for all users of Autodesk Fusion and Mastercam. Soft jaws—precision-machined inserts made of aluminum or steel—are used to securely hold delicate or complex parts during CNC machining.

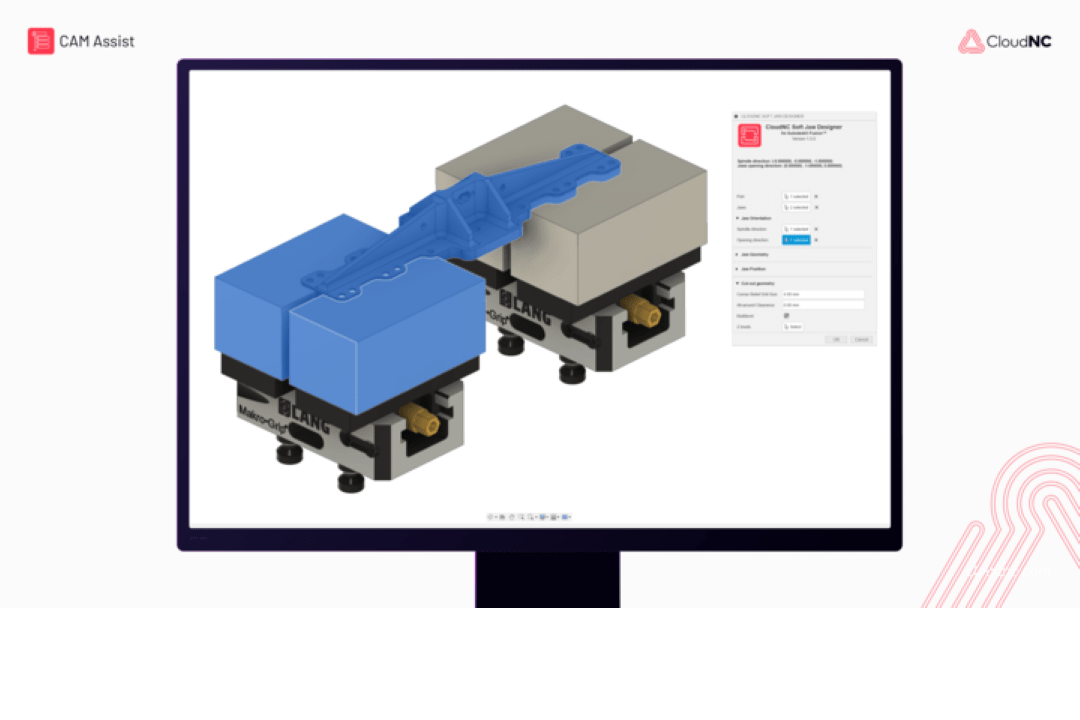

Traditionally, designing these components can take a skilled machinist 30 to 60 minutes per setup. Soft Jaw Designer cuts that time to mere seconds by automating the entire modeling process. With the plug-in, users simply position two blank jaw models around the part, click Generate, and receive fully detailed soft jaw designs that are ready for manufacturing.

Theo Saville, Co-founder and CEO of CloudNC, explained “Machine shops shouldn’t lose time designing fixtures. By making Soft Jaw Designer freely accessible, we’re giving programmers an instant solution that eliminates bottlenecks and helps them focus on high-impact tasks. It also demonstrates how much efficiency our technology can unlock.”

Once installed, the plug-in simplifies the entire workflow. Users no longer need to manually create complex sketches, run Boolean operations, or validate clearances. Instead, they define where the jaws will clamp the part, and the software handles the rest—automatically cutting negative geometry, applying machining allowances, and adding features like corner reliefs. The final result is fully editable, allowing for easy modifications. In practice, Soft Jaw Designer has been shown to reduce fixture design time by up to 90%.

Soft Jaw Designer integrates directly with CloudNC’s CAM Assist. After generating the jaws, users can send the assembly straight into CAM Assist, which automatically creates the toolpaths for both the part and the jaws—streamlining the entire setup for machining in just minutes.

CloudNC is redefining the manufacturing landscape through intelligent automation tools that improve efficiency, reduce programming time, and boost factory output. The company’s flagship product, CAM Assist, uses AI to automate key steps in the CNC programming process—from strategy development to toolpath creation—enabling machinists to produce optimized programs in a fraction of the usual time.

Founded in 2015, CloudNC operates from its London headquarters and Chelmsford-based factory, combining cutting-edge software development with real-world manufacturing expertise. CloudNC is supported by top-tier investors including Atomico and Episode 1 Ventures, and maintains strategic partnerships with industry leaders such as Autodesk and Lockheed Martin.