Robotics, automation, additive manufacturing, and data-driven systems are rapidly reshaping the metalworking industry. With so many innovations emerging, it’s becoming increasingly difficult for companies to stay informed and make confident decisions about which technologies are worth adopting. EMO Hannover 2025, taking place from September 22 to 26, is designed to support businesses in navigating these changes and choosing the right tools for growth.

According to Dr Markus Heering, Managing Director of the VDW (German Machine Tool Builders’ Association), EMO is more than a trade show. “It’s a global hub for industry professionals—manufacturers and users alike—to connect, share insights, and learn from one another,” he says. This exchange of ideas won’t be limited to exhibition booths; expert talks, themed pavilions, and live demonstrations will all provide valuable perspectives on where the industry is headed.

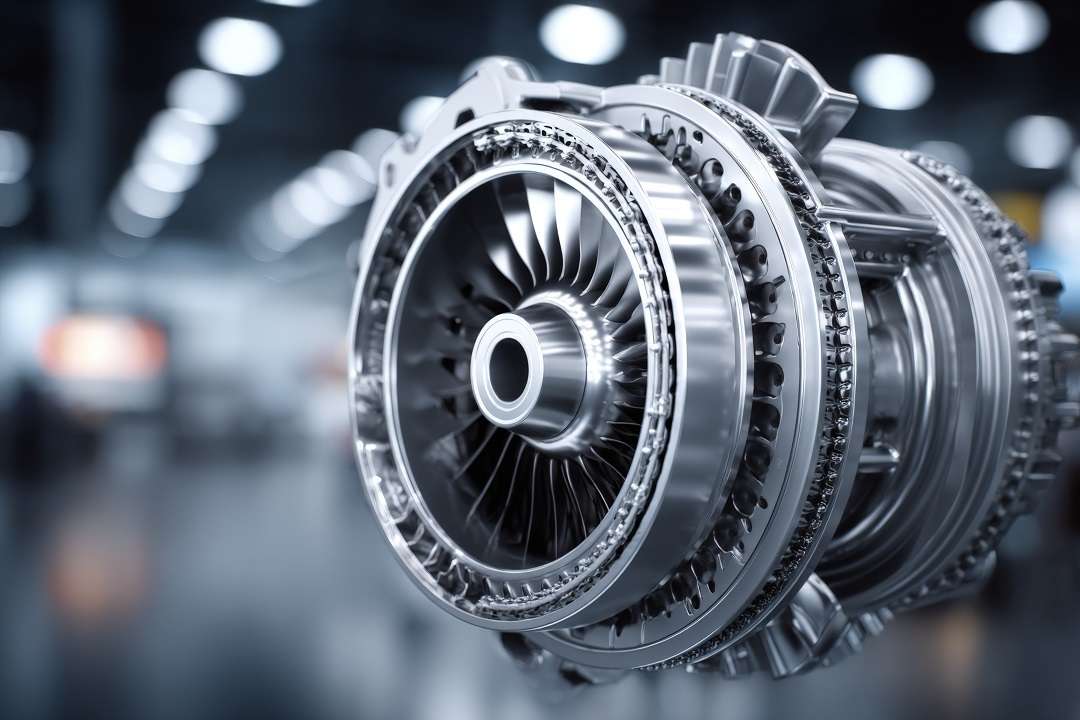

Many production sites are under pressure to modernize. Global competition, rising energy and material costs, and climate goals are pushing manufacturers to rethink how they operate. Sectors like aerospace, healthcare, and renewable energy require not only precision but also deep technical understanding. At the same time, the materials in use are evolving—they’re becoming stronger, lighter, and more durable, which demands advanced processing know-how.

As the labor market tightens, digital tools and automated systems offer real support. EMO Hannover aims to provide practical answers for companies looking to boost efficiency and manage workforce gaps through technology.

Visitors to EMO will find real-world solutions to common challenges. Whether you’re producing components for medical scanners or aerospace parts, your investments in machinery, robotics, or software must deliver clear value—either by increasing productivity or opening up new opportunities. Partnerships across the supply chain are also key, and EMO offers a platform for companies to connect with potential collaborators.

Key trends shaping the industry include automation, sustainability, digital connectivity, and machine learning. “Automation plays a central role, especially in the face of rising quality demands and labor shortages,” says Dr Heering. Today’s systems must be user-friendly and easily adapted to different production needs—whether you’re manufacturing at scale or working with one-off parts. Solutions range from basic handling equipment to fully autonomous setups, and EMO’s dedicated Cobot Area will showcase the latest in collaborative robotics.

Sustainability is another major focus. It’s not only about lowering resource use, but also about helping machines contribute to greener industrial practices. As Bertram Kawlath, President of the VDMA, noted recently, mechanical engineering has a key role to play in driving climate-conscious transformation. EMO’s Sustainability Area will highlight efficient technologies and how factories can integrate renewable energy, circular practices, and full life cycle planning into their operations.

Advances in connected systems and artificial intelligence are reshaping how production lines operate. Increasingly, machines come equipped with sensors and data capture systems to monitor performance. When processes are digitally linked, it becomes easier to spot inefficiencies, track output, and even predict maintenance needs before problems occur. EMO Hannover 2025 offers a chance to see how all these pieces come together—giving decision-makers the insights they need to move forward with confidence.