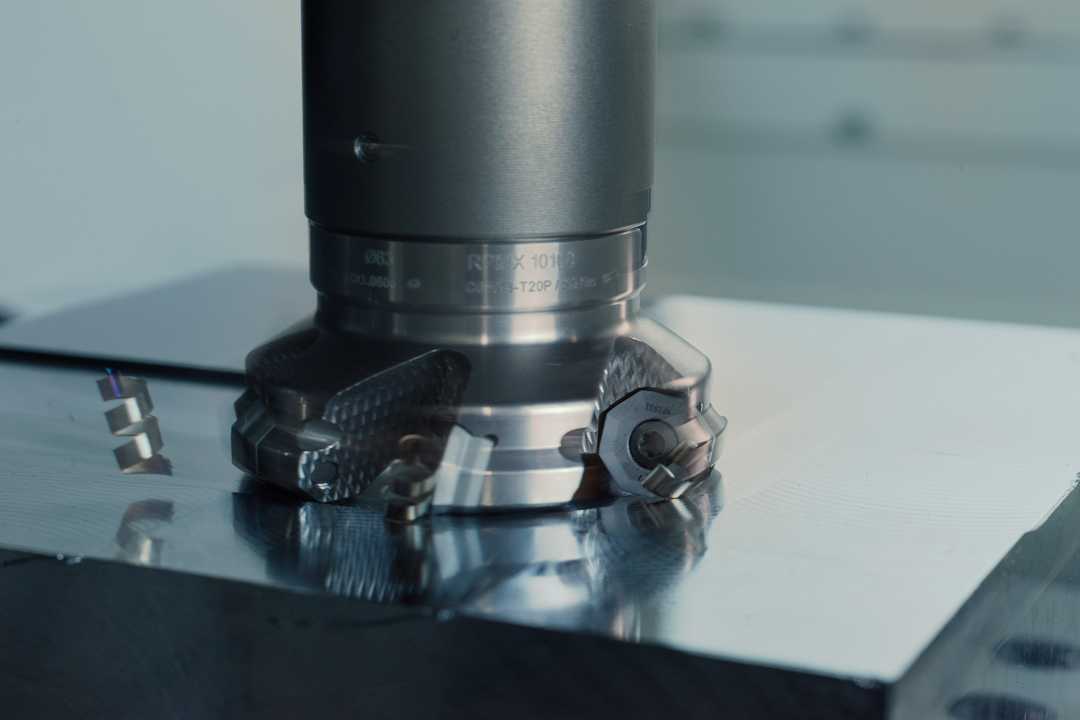

The latest generation of the Seco Octomill 06 Face Milling Cutter introduces significant advancements in usability, flexibility, and stability. Designed for precision and reliability, the cutter features a self-centering insert system for effortless, error-free positioning, along with a multi-insert pocket design that supports various insert types for diverse machining applications.

The self-centering inserts of the Octomill 06 enable quick and secure positioning with high repeatability. A long insert screw allows easy indexing without the need to remove the screw from the cutter body. Its innovative cutter-insert interface separates cutting edges from support surfaces, mimicking the durability of double-sided inserts while retaining the positive setting approach of a single-sided design.

“By keeping worn portions of the insert separate from support surfaces, we prevent performance issues and damage to unused edges,” said Tobias Jakobi, Seco Product Manager. “The self-centering feature also eliminates incorrect insert positioning, reducing instability, edge breakage, and costly work interruptions.”

With its right-handed design, straight cutting edge, and a high helix angle of +16°, the Octomill 06 minimizes radial and axial forces, ensuring smoother entry and exit, reduced back cutting effects, and even wear distribution along the cutting edge. This makes it an ideal choice for machining unstable setups or thin-walled components while maintaining high-quality production standards.

The Octomill 06 features a versatile multi-insert pocket design, enabling it to accommodate face milling, round, and moderate high-feed inserts. This flexibility allows a single cutter body to efficiently handle a variety of machining operations, reducing the need for multiple tools and enhancing overall productivity.

With its advanced design, the Octomill 06 excels in face milling, ramping, helical interpolation, and profiling, making it an ideal solution for diverse milling applications. This adaptability ensures precise performance across different machining tasks, optimizing both efficiency and tool life. Additionally, a diverse selection of insert grades and geometries ensures optimal performance across various materials, covering the P, M, K, N, S, and H Seco Materials Groups. With its enhanced stability, ease of use, and application versatility, the Octomill 06 is a go-to solution for manufacturers seeking precision, efficiency, and reduced downtime in face milling operations.