In the rapidly advancing world of manufacturing, where precision, adaptability, and innovation define success, HELLER Machine Tools stands as a shining example of excellence. For over a century, HELLER has been synonymous with pushing boundaries and delivering solutions that have shaped industries across the globe. Their journey through 4-axis and 5-axis machining solutions represents this relentless pursuit of innovation, and at IMTEX 2025, the company is ready to showcase its latest groundbreaking technologies.

IMTEX 2025, one of the most anticipated events in the global manufacturing calendar, is set to take place at the Bangalore International Exhibition Centre this January. The event promises to be a pivotal moment for manufacturers and industry professionals from around the world to explore the latest advancements in technology. Among the highlights will be HELLER’s innovations in machining, with an emphasis on the versatile H Series 4-axis machining centers and the highly anticipated 5-axis machining solutions, including the F 5000 and F 8000 models.

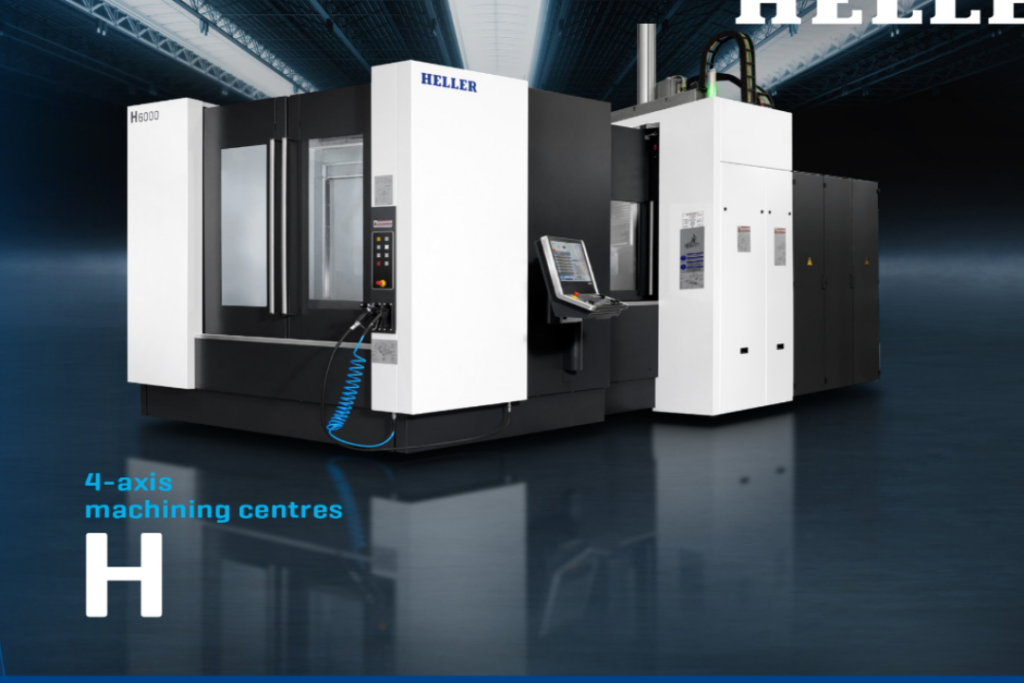

HELLER’s commitment to precision and productivity is evident in the technologies that it brings to market. The H Series 4-axis machining centers are designed to meet the increasing demands for high-speed, high-precision machining in industries such as automotive, aerospace, and mechanical engineering. These machines are engineered to streamline production processes by significantly reducing cycle times while maintaining the exacting standards required by industries that rely on precision machining.

Automotive manufacturers, for instance, benefit from HELLER’s ability to enhance efficiency without sacrificing quality. HELLER’s technology not only speeds up throughput but also improves positional tolerances, ensuring that each component meets the rigorous specifications necessary for safety-critical applications. In industries like automotive, where time-to-market is of the essence, HELLER’s machines help manufacturers stay ahead of the curve.

“The automotive sector constantly pushes the boundaries of innovation, requiring solutions that not only enhance production speed but also guarantee quality and precision. At HELLER, we understand the evolving needs of the industry, which is why our machining solutions are designed to offer exceptional performance, reduce operational costs, and help manufacturers stay competitive,” said Mahesh Tyagi, Managing Director, HELLER India.

As of now, HELLER has more than 10,000 machines running in the automotive industry worldwide, providing support in the production of engine components, chassis, suspension systems, and more. The company’s high-precision machines ensure manufacturers can keep pace with growing demand and meet the technological challenges of the modern manufacturing world.

In addition to the 4-axis machines, HELLER is unveiling its Friction Stir Welding (FSW) technology, FSW is a revolutionary welding process, ideal for non-ferrous metals, that ensures high-quality welds without cracks or pores. This innovative technology boosts the structural integrity of products, making it particularly valuable for industries requiring high reliability.

“Friction Stir Welding technology is a game-changer for manufacturers working with non-ferrous materials. With no filler material required, this process eliminates many of the consumables associated with traditional welding, reducing operational costs. Moreover, it is available on both our standard 4-axis and 5-axis machining centers, making it a versatile solution for a wide range of industries,” added Tyagi.

Another key aspect of HELLER’s showcase at IMTEX 2025 will be the company’s next-generation 5-axis machining centers, including the F 5000 and F 8000 models. The F 8000, in particular, is a breakthrough in engineering. Unveiled at the AMB International Exhibition for Metalworking in 2024, this machine combines a compact footprint with unprecedented precision. It is specifically designed for industries like aerospace and mechanical engineering, where tight tolerances and intricate geometries are commonplace. The F 8000 is a true masterpiece, offering manufacturers the ability to perform highly complex machining operations with unparalleled accuracy.

“HELLER’s 5-axis machining centers, particularly the F 5000 and F 8000, are a testament to our dedication to advancing machining technology. These machines are designed to deliver unparalleled precision and versatility, enabling manufacturers to tackle some of the most challenging machining tasks with ease,” said Tyagi.

As the demand for smart manufacturing continues to rise, HELLER is also focusing on the integration of automation and digitalization into its solutions. The company’s machinery is equipped with automation features, streamlining production lines and improving efficiency. By leveraging digital tools and connected technologies, HELLER helps manufacturers optimize their operations, reduce downtime, and increase overall productivity.

“IMTEX 2025 is the perfect platform for us to showcase how HELLER’s solutions are driving the future of manufacturing. Whether it’s the advanced features of our 5-axis machining centers, the innovative Friction Stir Welding technology, or our cutting-edge automation solutions, we are excited to share our vision for the future of precision manufacturing,” said Tyagi.

For manufacturers looking to take their operations to the next level, IMTEX 2025 is the must-attend event of the year, and HELLER’s presence is sure to be a highlight. Join HELLER in Hall 4, Stall C101 at the Bangalore International Exhibition Centre.