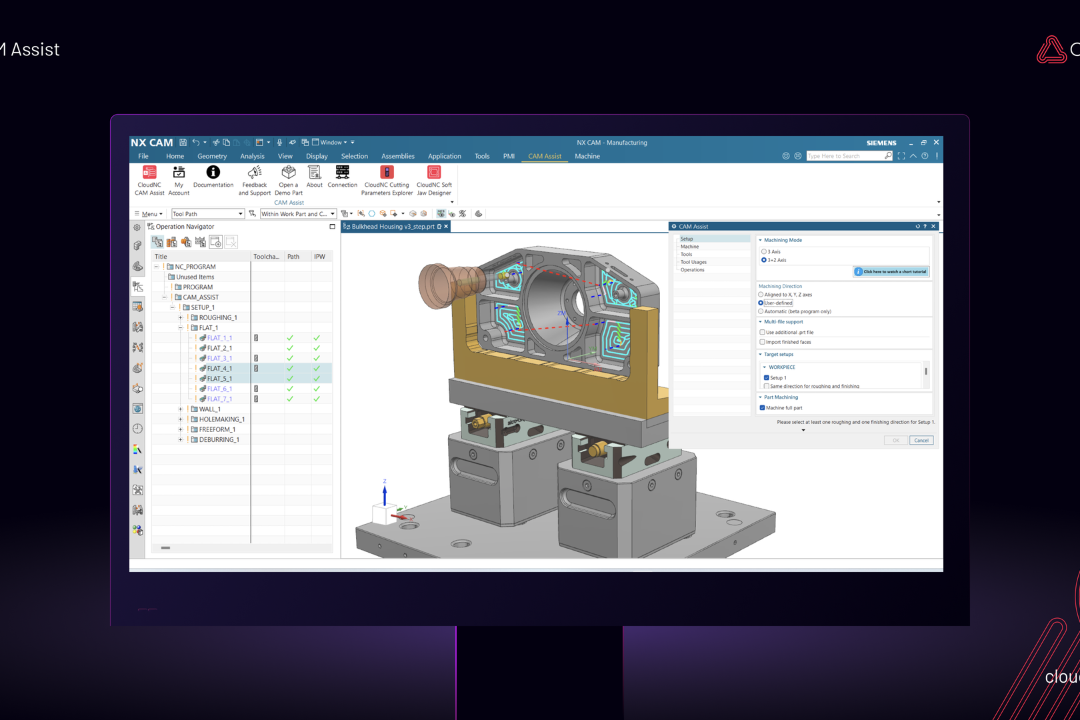

CloudNC, a leader in manufacturing technology, has announced that its CAM Assist solution, which leverages AI to develop machining strategies for 3 and 3+2 axis CNC machines, is now available for Siemens’ NX™ CAM users.

This innovative AI-enabled add-on integrates seamlessly with Siemens’ NX software, one of the most widely used CAM platforms across major industries like aerospace, automotive, and industrial machinery. By making CAM Assist accessible to a broader audience, CloudNC aims to help CNC programmers create toolpaths and machine parts with unprecedented efficiency.

Theo Saville, CEO and co-founder of CloudNC, said, “Siemens’ NX is used by industry leaders in critical sectors such as aerospace, defense, and automotive. Streamlining the programming process is essential for manufacturers to stay competitive. CAM Assist enables CNC programmers to significantly reduce the time spent on toolpath creation, enhancing productivity and efficiency.”

Armin Grunewald, Vice President at Siemens Digital Industries Software, added, “At Siemens, we are committed to offering cutting-edge solutions that accelerate part manufacturing. Integrating CloudNC’s AI-driven technology into NX CAM exemplifies our mission to provide our customers with innovative tools that enhance their processes. The openness of the Siemens Xcelerator portfolio enables technology partners like CloudNC to integrate their specialized solutions rapidly, expanding the range of digital manufacturing capabilities we offer.”

CAM Assist uses advanced AI and computer science to automatically generate machining strategies in minutes or seconds, depending on complexity—a task that would typically take CNC programmers hours or days to complete manually. This time-saving technology helps manufacturers overcome a common bottleneck in production by reducing both programming time and cost estimation, boosting overall productivity and enabling shorter lead times.

CloudNC’s vision is to bring about single-click manufacturing, and with CAM Assist, the company is reimagining precision machining. By using AI to speed up CNC CAM programming, CloudNC helps manufacturers save hundreds of machine programming hours annually.

Founded in 2015, CloudNC combines expertise in computer science and physical manufacturing, operating out of its headquarters in London and a factory in Chelmsford. The company is supported by prominent venture capital firms Atomico and Episode 1 Ventures, as well as strategic partners Autodesk and Lockheed Martin.